ARCHIVE FOR THE ‘features’ CATEGORY

Jun 04, 2019 • Features • 3D printing • manufacturing • Additive Manufacturing • Parts Pricing and Logistics

An industrial products manufacturer has a large portfolio of spare parts in its portfolio. It has 10 year service contract with its customers implying that the company must be able to deliver spare parts on time for 10 years to its customers even though the product may longer be produced. Thus, the company has to maintain inventory of some of those spare parts. Such inventory costs run into millions of dollars. Many of those spare parts are produced by suppliers. Demand for those spare parts are low and unpredictable.

On Monday morning, the spare parts manager received a call from a customer in another continent “ Mr. Paul, our equipment is out of action as it cannot be started in the morning shift. My maintenance guys confirmed we need to replace a part, supplied by you and we do not have it in inventory. I am sending you the part number. Please deliver it within three days otherwise there will be heavy loss.” Mr. Paul checked the part number in the ERP and found that they also do not have in stock.

He found out who the supplier is and called him up. The supplier replied saying that they cannot make only one piece. They will need an order size of at least 20 and it will take 1 week. What will Mr. Paul do? He remembered that the Vice President (VP) of Supply Chain was talking about 3D Printing of spare parts in the last meeting. Can the part be printed? How will Mr. Paul figure that out?

He refers to the presentation by VP- Supply Chain and finds the name of a company called 3D Hubs (UPDATE: 3D Hubs is now Hubs). Mr. Paul checks out the website of 3D Hubs and found that he can upload the drawing of the parts and get an analysis for printability along with a quote. He uploaded the drawing, got the quote for delivery within three days and went to his boss.

His boss, Mr. James said “Are you crazy? How will I be able to justify that price? Also, have you noticed that they are not printing our part using our specified material? This will never work.” Mr. Paul tried to argue “This is a very strategic customer for us. If they are not satisfied and cancel the service contract, it will be a big trouble for us. We can say that they can run their equipment with it until an actual replacement spare part is produced and delivered by the supplier. I can talk to R&D about the approval for the deviation in material. It doesn’t seem to be a big change.” Mr. James said “You are taking a big risk, Paul. If you want to try, go ahead.”

In the end, everything turned out well. That part was produced using additive manufacturing (AM) and delivered on time. Paul received appreciation for his efforts. VP- Supply Chain was very happy and said to Paul. “Now, I want to evaluate our entire spare part portfolio and develop a systematic process of evaluating which of those parts can be printed and which cannot. It will be great if you can evaluate our portfolio and present in our next month’s meeting.”

Paul has 10 years of experience in spare parts but he does not know much about 3D Printing. How can we help Paul? I am sure that there are many people like Paul in large industrial manufacturers, who need similar help. Lets try to outline a steps-by-step process for selecting spare parts suitable for additive manufacturing.

Step 1: Identify the objectives

Some potential objectives for producing spare parts using AM can be:

• Supply risk reduction;

• Lead time reduction;

• Inventory cost reduction;

• Ensuring local content;

• Minimizing loss of production;

• Reducing carbon foot print across life cycle.

Companies can decide the most relevant ones from those and provide relative importance of those using a method called analytic hierarchy process. Instead of directly assigning importance weights to each objective, experts within the company can make pairwise comparison of the objectives using a scale (for example 1-3-5-7-9) and derive the importance weights.

Step 2: Identify the factors to be used for screening the spare parts for AM suitability

Some factors, which can be used for screening the spare parts for AM suitability can be as follows: It is important to note that the company should have data on the following factors to be considered for screening.

If such data is not available or available in different IT systems or in physical form ( i.e. drawings with dimensions and material specifications), it will be difficult to include those at the screening stage.

1)Demand and demand uncertainty of the parts

Parts with low and uncertain demand are more suitable for spare parts

2) Overall part size

(Part must fit build volume of the equipment) As the equipment for different AM technologies have build size restrictions, part-size is usually a restriction, if it cannot be fitted in the build chamber. Sometimes changing the orientation of the part may be needed to fit it into the build chamber, but it might require additional support structures and may increase the overall production time. Decisions about part orientation in the build chamber can be taken only for the selected parts and not at this stage. The company can specify the upper limit of size or a range of sizes of parts, which they would like to consider

3) Materials

Not every material can be printed. Thus, parts whose specified materials can be printed can be screened when a company is starting on its journey of producing spare parts using AM. Later, alternate materials which closely match the specifications can be explored.

4) Supply lead time

Parts with long supplier lead time for conventional manufacturing can be more suitable for producing using AM as overall lead time can be reduced. A company may decide to specify either the lower limit or range of lead time, which they would like to consider.

5) Purchase price or unit cost

High priced parts, in general, can be suitable for AM but some high valued parts may be infeasible because of their size or materials etc.

6) Value of inventory across all locations

Usually parts with high inventory value can be good candidates to be produced using AM. High value of inventory can be due to high number of parts in stock or due to high prices. Sometimes, if a lot of stock is available, a company may decide not to proceed with producing such a part using AM. Some other company may decide that they would like to get rid of that stock and hence it may be worth producing those using AM. A company may also decide to include either price or inventory value as a screening factor.

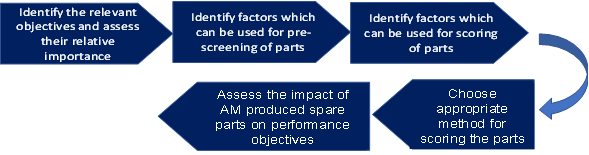

Figure 1: Step-by-step approach for selecting spare parts suitable for AM

Step 3: Identify the factors to be used for scoring the spare parts for AM suitability

Some potential factors for scoring spare parts in terms of their suitability for AM can be as follows:

• Lead-time;

• Unit cost;

• Criticality in terms of influence of the part for equipment shutdown;

• Demand predictability measured as standard deviation of demand;

• Supply risk in terms of number of suppliers;

• Minimum order quantity.

The screened parts can be scored based on the above factors and how the factors are related to the objectives. Parts with long lead time, high cost, high criticality, low demand predictability, high supply risk and high minimum order quantity in the existing manufacturing process will be more suitable for AM.

Step 4: Choose appropriate method for scoring the parts

There can be multiple approaches to score the spare parts in terms of suitability to be produced using AM.

We mention some basic guidelines below:

1. Multi-criteria decision making approach (MCDM) –scoring parts on factors and linking factors to be objectives (suitable for less number of factors and less number of parts).

2. Logic decision diagrams, cluster analysis and fuzzy inference system (suitable for large number of parts, medium number of factors but strong interrelationships of factors and objectives). If the factors are dependent on each other and how they influence the objectives depends on the levels of the factors i.e. low, medium and high, logic decision diagrams can be built to score a part using different decision rules. In terms of disagreement between experts about the relationships, the relationships can be expressed as fuzzy numbers and fuzzy inference system can be used to score the parts.

3. Cluster analysis and MCDM approach for ranking of part clusters and within cluster ranking of parts (large number of diverse parts, limited to medium number of factors and independence of factors) If the factors considered are independent but the spare parts portfolio is very diverse, it will be necessary to cluster the parts, rank the clusters and then rank the parts within the clusters.

4. Bottom-up expert driven selection using a questionnaire or selection protocol (no data available or not possible to do quantitative analysis) If no data is available in digital form to score the parts, it is prudent to use the expert judgment of the service personnel or maintenance technicians. But, as those persons may not be aware of AM technologies, it is important to demonstrate to them what is possible using AM through workshops and ask them to suggest spare parts, which they find most difficult to get. Companies can also potentially run internal competitions to identify some spare parts to start with.

Step 5: Assess the impact of AM produced spare parts on performance objectives

Once some spare parts are identified, the next step is to develop business cases for the parts. But, those can be done once the appropriate technologies and equipments are identified. For that purpose, a database of all available AM equipments, the technologies they use, the materials they use, the build chamber of the equipments, the surface finish achievable need to be documented.

For the spare parts which are scored high in terms of their suitability for AM, the most appropriate technologies and equipments can also be shortlisted. Then total-cost of ownership based cost models need to be developed to understand the economic implication of producing the parts using AM. The relevant cists which need to be considered are materials, production, energy, labour as well as the savings in inventory and transportation costs over the lifecycle of usage of the parts for different demand scenarios.

Quotes from different service providers can also be used as a reference for taking the final decision. Once a company has done this exercise and identified a few feasible parts, some machine learning techniques can be used to identify the patterns amongst the most suitable parts so that the process can be automated when new parts are added to the portfolio.

Jun 03, 2019 • Features • Jan Van Veen • management • moreMomentum • Burning Platform • Service Innovation and Design

Quite often, when talking with business leaders and clients, I hear the problem that the organization and its people are not that open to innovate and change as they already have good performance and there is no clear threat visible yet. They experience it as a lack of “sense of urgency”: there is no “burning platform” for innovation and change.

A common approach is to either wait until the situation gets worse or construct a (mini)crisis to increase and maintain a sense of urgency.

However, the question is:

• Do we really need a burning platform to innovate and change? And;

• What are the downsides to building change and innovation around a burning platform?

In this article I will share five reasons why a Burning Platform is bad for sustainable innovation and change.

Why a burning platform is bad for innovation?

1.You are too late

Typically, the trends which create threats or opportunities develop a long while before becoming an obvious burning platform. First, there are the first weak signals for a trend. At this time, it is still hard to accurately predict what will happen and when. Maybe different way signals are contradictory.

So often, these weak signals are being ignored by the majority. After some time, we see the first competitors moving, but actually also struggling to successfully address the threats of opportunities. Their initiatives seem to be failing. As a result, the majority still waits. Once the leading competitors are having their first successes and the trends become emerging, the burning platform becomes visible.

But now, the leading competitors have learned and built capabilities and can scale. While the lagging majority is still trying to find the right questions, let alone the right answers. They are dropping behind the leading pack in their industry. They are too late.

2. You get a deeper performance dip

The urgent situation of a burning platform means there is a critical situation which requires a rapid response and rapid results.

The topic is becoming increasingly dominant in the daily activities of everyone in the organisations. All hands on deck!

It starts distracting attention from the daily work of running the business. The overall performance will suffer more and longer than if the urgent can critical situation would have been prevented by innovation and change at a much earlier stage.

3. You disengage your valuable people

In general, a necessity to change – the burning platform – will create higher stress levels which will impact altitude and behaviour towards change. The more critical and urgent the necessity, the bigger the chances are for stress levels which will trigger defensive reactions like fight, flight or freeze.

Too often, we see the stress levels resulting in internal fights, pointing fingers, pushing problems to other teams and the best talents moving to other companies.

These are negative sentiments, which can be transformed into a positive and bonding sentiment within teams for a while, but not for long.

4. You miss the best solutions

The defensive fight, flight or freeze behaviour mentioned above, also triggers short term reactive thinking and blocks constructive and creative thinking.

When solutions require deeper analysis, being open to new types of solutions and require collaboration between different teams or department, this reactive short-term thinking is counterproductive.

The high level of stress increases the risks of not seeing the real problems or opportunities, not finding the right solutions and not doing what it really takes to get the results.

"It starts distracting attention from the daily work of running the business..."

5. You increase the risk for failure

During the first attempt of implementing a new solution, we should expect hiccups. Instead of experiencing this as a failure, everyone should see this as learning.

They should be able to have a constructive and forward-looking mindset to collectively understand why it is not working yet and what interventions are required to get it right. With a flight, fight or freeze attitude, the chances are bigger people will blame others or the conditions, find reasons to justify the disappointing results and give up.

For sure, we know about success stories where companies successfully pivoted their business during a crisis, like IBM. We also now the examples where companies miserably failed during a crisis and did not survive.

The better alternative: Purpose

The better alternative is what the leading and dynamic manufacturers do very well: the rally their employees, their clients and their partners with a strong and compelling purpose which makes continuous innovations and change the natural, logical and compelling thing to do.

Like everyone at Philips Healthcare is committed to transforming our healthcare by offering and developing integrated solutions (hardware, software, services) for people to live healthier, prevent deceases, be diagnosed quicker and more accurately, receive better and less intrusive treatment and receive the care they need at home.

Or like Tesla is accelerating the transition of sustainable energy and transportation with electric vehicles, better batteries and solar panels. This approach will be more rewarding for everyone, lead to sustainable success of the business and reduce the chances of entering periods of critical decline of performance. It will avoid you being on a burning platform.

The Essence: People Do change!

I believe that people do change and drive innovation, if there are compelling reasons and not too many obstacles. After all, that is the only reason the world is changing so rapidly.

Too many organisations do a bad job in providing compelling reasons and good job in creating obstacles. That is the reason organisations struggle in keeping up the high pace of changing world.

Leading, dynamic and innovative companies set themselves apart by maintaining a clear and compelling purpose, direction and strategic intent as well as e great environment for collaborative change and innovation.

Conclusion and recommendation

In this article, I described five reasons why the common practice burning platforms and sense of urgency are bad for innovation and change. I also briefly described the best practice alternative: build and maintain a compelling purpose for everyone to be proud of and to work on.

If you are on the same page and would like to take next steps, I would recommend you to:

• Assess what your personal view is on the reason your business or department should change and innovate differently or quicker.

• Assess to how compelling this is for the 1) shareholder, 2) boardroom, 3) employees and 4) clients.

• Evaluate and enrich (your view of) the purpose of your company or your department. What is your relevance for the industry, for your clients and for the society?

• Reach out to me for a discovery or sound-boarding session. I am happy to help and also curious to learn from your experience.

I am confident this will bring you actionable insights for your department - if not for the business as a whole. Good luck!

Jan van Veen is Founder and Managing Director at moreMoumentum.

May 31, 2019 • Features • consumer electronics • Mike Pullon • Hardware • Rugged devices • The Field Service Podcast • Varlink

In the latest Field Service Podcast, Mike Pullon discusses if rugged devices will ever be replaced by their consumer cousins.

In the latest Field Service Podcast, Mike Pullon discusses if rugged devices will ever be replaced by their consumer cousins.

With the boundaries of consumer and rugged becoming more blurred, we spoke to Mike Pullon, CEO and Founder of Varlink - an outfit that distributes specialist rugged devices - if high-street phones and tablets will ever replace their rugged counterparts.

May 30, 2019 • Features • future of field service • WBR • field service asia

WBR Asia’s Wendy Zheng, explains why the Asia Pacific region has become a hot bed of field service innovation...

WBR Asia’s Wendy Zheng, explains why the Asia Pacific region has become a hot bed of field service innovation...

Field service is on an upward trajectory all over the world, and one region is leading the charge to challenge the US dominance of the industry. The worldwide market size of the field service management industry is expected to grow to $5.08 billion by 2023, with a compound annual growth rate of 14.7%.

This growth is being driven, in part, by the onslaught of innovative new technology which is making the whole industry more efficient and cost effective. Mobile applications, wearable devices, cloud hosting, and the Internet of Things (IoT) are all helping field service engineers and the administrative staff who support them to deliver superior customer experience.

However, while North America still holds, and is expected to continue holding, the largest market share, the Asia Pacific region is predicted to exhibit the most rapid rate of growth during the period. With the increase in the number of Small and Medium-sized Enterprises (SMEs) in the emerging countries, such as China and India, competition in APAC is expected to grow at a because of automation in various business processes, including job scheduling, billing and invoicing, and service delivery.

Asia Pacific

One reason for this rapid rate of growth is attributed to the fact of the emerging markets of the region (such as India and China) being home to a large number of small and medium sized enterprises.

The continued increase in the number of these enterprises leads to a sympathetic increase in competition. This, in turn, drives the introduction of innovative technology, such as automation for various business processes such as job scheduling, billing and invoicing, and service delivery.

“Asia Pacific is expected to witness the highest CAGR in the global field service management market during the forecast period,” writes Globe Newswire. “This is primarily due to large-scale industrialization in Asian countries such as China, India, and Japan. With enhanced geographic zones and a high client base, the Asia Pacific region is expected to exhibit a strong growth in the field service management market. Increasing number of technology users in Asia Pacific region further propels the growth of field service management market in this region.”

Competition has always driven innovation as individual companies try and outdo one another in the eyes of their clients. It’s the same reason why the greatest leaps forward in technology occur during times of war, with the business world being just as susceptible to an arms race as the military can be.

Cloud Field Service Management

One of the new technologies which is particularly helping the Asia Pacific region grow at a rapid rate is the adoption of cloud-based field service management systems.

Cloud-based field service management solutions continually harvest and archive data, allowing businesses to use the resultant historical archives to identify trends and patterns and improve the necessary processes, leading to a better customer experience.

For example, it could be identified via automated cloud-based field service management tools that a certain part or component seems to have a recurring fault. Once this has been identified the manufacturer of the component can be contacted so they can make the necessary design changes, or the field service company can change to a different provider.

Likewise, data can help identify factors which are leading to field service engineers making wasted journeys or becoming delayed. Changes can then be made to scheduling or work shifts to make sure the right people are always in the right place, at the right time. Similarly, when it comes to spare part stock control, if a particular item is shown to regularly run low, purchasing can be adjusted as necessary.

Final Thoughts

The Asia Pacific region is leading the way in adopting this kind of cloud-based technology. It is technology such as this, combined with the competition being driven by the increase in small and medium sized enterprises, which is helping these emerging countries take the fight to North America as the new hot contender in the global field service marketplace.

“There is increasing demand to increase productivity and reduce operating costs,” writes IT Tech Herald. “Players are adopting field service management solutions to enhance customer experience, with customer demands and the logistics of managing field teams continuing to increase in complexity. Emergence of new technologies such as IoT and mixed labor models are promoting the market growth. Thus, increasing demand to enhance productivity and advent of various technologies are anticipated to drive the market growth during the forecast period.”

Asia’s position as the up and coming new stage for field service is sure to be a hot topic at Field Service Asia 2019, Asia’s Leading Conference for Service, Support and Customer Care on 12-14 November, at the Amara Sanctuary Resort, Sentosa, Singapore.

May 29, 2019 • Features • copperberg • future of field service • Field Service Summit • Parts Pricing and Logistics

Would you walk into a pub that served you a warm beer the previous time? Or, go back to this fine dining restaurant with your partner if it was noisy and unclean? One word that can make or break it for the service business is ‘Experience’.

With customer satisfaction being the buzz word in the past years, now the new trending words are ‘Experience Economy’, ‘Customer Delight’, and ‘Good-feel Service’. The trend is very common in the B2C sector which has led to terms like ‘Uberized Service’, ‘Amazon like Delivery’ or ‘Disney like Experience’.

This wave of keeping customers happy and providing them with a great experience has to become a priority on the list of the majority of Field Service Directors today. With the quest to create the perfect value proposition and customer experience comes in the various challenges that these leaders in manufacturing face today.

Recently, I had a fantastic opportunity to moderate a round-table discussion along with Kris Oldland, Editor of Field Service News about the Challenges that Service Leaders Face today and the future technologies in Field Service and Spare Parts at the Spare Parts Summit Summit in Coventry, UK.

One important observation was the interlinking of issues with spare parts and field service. The service leaders faced challenges in obsolesce management, spare parts management, data collection, utilisation and analysis along with field workforce training and planning.

With the advent of digital tools, faster production and time to market, one big challenge for Service Leaders today is obsolescence management as it has become increasingly challenging to predict and prepare for the future. IoT and connected machines have made predictive maintenance easier and helped the service organisations to move into the proactive space than the reactive space. One challenge still remains with break-fix due to user mismanagement, negligence or insufficient training.

Although IoT allows companies to note some cases of misuse and offer training proactively preventing damage to the machines and need for servicing prematurely. The service leaders have accepted that there will always be break-fix with machines whether it is due to an unforeseen circumstance or a user issue. So the goal in these instances is to have enough data to be able to get a technician with the right spare parts to the location and get it fixed immediately.

"One important observation was the interlinking of issues with spare parts and field service..."

This is a shift from the older model of a technician visiting to collect information, making a fault report to get the spare parts and revisiting the customer to fix the issue which is a higher cost for the service company and loss in uptime for the customers. Tracking of spare parts and more specifically ‘Having the rights parts at the right place’ is also an issue being tackled currently by the service leaders.

Some leaders are concerned about the tracking of spare parts as they become ‘lost’ with technicians, in spare part boxes or in inventories. Technologies like RFID readers, GPS tags could play a big role in actively tracking the spare parts to make sure the parts can be delivered to the right place when required.

The manufacturing, service and aftermarket space today is in a fantastic rush for data and today is commonly referred to as the new gold or oil. Kris Oldland had an interesting take on how this gold can be dug out but will still be useless unless refined and put it in the right form. One challenge with data is also getting data from the right source.

Similar to ores to extract gold, if the content of the ore is bad, the gold will be very expensive to extract and the return on investment will be low or negative. Data has a similar proposition today. Companies have started asking, how much data is enough data and which data is good data. With better data processing, artificial intelligence and machine learning making progress, the data analysis and processing woes should be answered more effectively in the near future.

The challenges cannot be addressed with a magic wand or just ignored, but being able to address them is a progressive first step. Collaboration with the customers and getting them involved in the whole process of solving the challenges can also boost progress for the service organisations.

To sum it up according to a Forbes quote,’An experience is not an amorphous construct, it is as real an offering as any service, good or commodity.’

May 28, 2019 • Features • Hardware • janam • Rugged devices • Varlink

Varlink’s Meet the Manufacturer event is firmly established in the field service calendar. Mark Glover attended the event, held at Leicester City Football Club, to see the latest rugged devices and meet those who play a key role at the gathering...

Varlink’s Meet the Manufacturer event is firmly established in the field service calendar. Mark Glover attended the event, held at Leicester City Football Club, to see the latest rugged devices and meet those who play a key role at the gathering...

In 2016 and against all odds Leicester City Football Club provided one of the great stories and, indeed shocks, in world sport by winning the English Premier League. When the Midlands team finally lifted the championship trophy at their home ground, The King Power Stadium in May that year, few could believe their achievement, the feat made all the more remarkable that only 18 months prior they were eyeing a potential relegation to the league below.

As a long-suffering football fan - I support West Ham - Leicester’s plight gave us smaller teams hope; that the goliaths of Manchester City and Chelsea can be overcome; that it’s not all about rich chairman and money; that fairytales do come true. You’ll have to forgive my tenuous diversion here. I’m conscious the focus of this piece is not football but on discovering the venue for Varlink’s Meet the Manufacturer (MTM) event would be the King Power Stadium - an event my editor sent me to cover - then you’ll allow me the misty-eyed opening paragraphs.

That said, in service, there is much talk of disruption and how companies should look to challenge what’s gone before in order to evolve and stay ahead and in a way, Leicester’s title winning season could be seen as the ultimate ‘disruption’ to the league’s status-quo and rigid hierarchy, and while the team haven’t joined the elite ranks of super clubs (Manchester City, Chelsea etc.) they are now firmly established as a Premier League side both financially off the pitch and with their performances on it.

Disruption meanwhile in hardware, specifically hardware in service is not as frequent, which doesn’t mean it’s not evolving; far from it. Service software providers – quite rightly - are extremely reticent in altering their hardware foundation as Mike Pullon CEO of Varlink explains. “A company that writes software for a niche, field service opportunity, whatever it is, is actually far more focused on their own business and the need to change is often driven out of necessity rather than any great desire,” he says. “When you’re writing your software, you’re enhancing your software, you’re taking care of business, you’re looking after your customers. The last thing you want to do is change the hardware platform you use.”

Mike founded Varlink in 2005. The company, a leading distributor of barcoding and data capture and EPOS products, feeds the service industry with rugged devices and hardware. Now in its 14th year, the firm’s annual MTM event serves to bridge the gap between customer and manufacturers, which today includes, among others, Zebra, Honeywell and Data Logic. Given the longevity of the event, I ask why it is so important for customers to see and experience the devices on show.

“Where do they go for their knowledge?” he asks. You go to the internet, you look at some websites and you actually find one product looks much the same as another. You don’t get a chance to feel the weight, feel the quality. It sounds really basic, but you know, until you hold one of those devices...where are the buttons positioned? How tactile is the screen? What’s the robustness? What’s the resilience? What are the charging options? So there are no UK shows that bring as many specialist, some might say niche, manufactures together.”

Mike suggests marketing emails and tweets replacing conversation between manufacturer and a specialist systems company, particularly those in niche verticals – which service tends to operate in – is missing the mark, creating a space for the event. “The communication between a hardware manufacturer and a specialist systems company, somebody providing for a particular vertical, has become stretched,” he says.

“There’s an assumption that email communications are going to carry the message about product, technology, opportunities to a customer base that’s just waiting for that communication. The last few years we’ve seen the slimming down of that conversation.”

Among the larger, big-name manufacturers such as the aforementioned Zebra, Honeywell and Datalogic and Janam Technologies. They produce operating system platforms and rugged hardware which they distribute to a reseller or software house to tailor, for example, a picking or delivery task. Robert Hurt is the firm’s EMEA General Manager and we find a quiet corner, among the beeps of demos and buzz networking, to discuss the company’s philosophy.

“Our approach is to provide people with a business tool that will work for as long as we can possibly keep it going,” he says, “and we’ll provide a service for as long as we’re able to obtain the components in order to do that. The differentiation for us is about providing a level of service.”

Compared to their consumer counterparts, rugged devices have a longer life. Failing batteries which are built in to ubiquitous Samsung and Apple smartphones are the common cause of failure and ring fence the two year turn around in buying habits. Having removable batteries in rugged devices means hardware can last a lot longer and keep the service technician active with the same device. “If you’re out on the road, you might not get to base for a couple of days,” Robert explains. “So we have removable batteries, which means you can take a spare battery and pop in this replacement battery. You can’t do it with an Apple phone and you can’t do it with a Samsung phone because it’s sealed giving it a limited life. We are still servicing and supporting devices we installed 10 years ago. They’re running simple business applications such as receiving a task and taking a signature, but it does the job.”

Janam do the vast majority of their business with re-sellers, who are a key demographic of visitors to MTM. I ask Robert how important the event is to the firm. “Every meeting, every conversation is worthwhile,” he tells me, “Everybody you meet is somehow connected to the industry, either as a supplier or as a customer or a reseller. We’ve been coming for as long as I’ve been at Janam. It’s always an interesting venue and an enjoyable thing to do.”

I shake hands with Robert, turn off my dictaphone and sip the final dregs of my coffee. Heading for the exit, I catch a glimpse of the football pitch, a bright, lush green that looks as smooth as a bowls lawn. Robert’s right. This is an interesting venue and I’m already looking forward to next year’s MTM event. For now, though, I’ll continue to believe that my team West Ham might one day perform the same miracles as Leicester and I have Varlink to thank for giving me that hope!

May 27, 2019 • Features • Management • Software & Apps • Michael Blumberg • Field Service Insights • Mize

Customer Experience is the single most important factor in driving customer loyalty and retention. In fact, market research studies show that it costs five times as much to attract as new customer as it does to keep an existing customer satisfied. Repeat customers also spend on average, 67% more than then one-time buyers.

Furthermore, just a 5% increase in retention can yield profit increases in the range of 25% to 95%. Let’s face it, the customer experience does not end once customers make a purchase. It is just beginning. Original Equipment Manufacturers (OEMs) not only have a responsibility to keep their customers satisfied through-out their buying journey and ownership lifecycle. They also have an opportunity to strengthen their relationship with customers and create more value for them by providing quality, aftermarket services.

There are many factors that influence Customer Experience when it comes to field service. The two most important factors by far are speed of service resolution and first time fix rate. A service provider can excel in every other area of consideration. For example, courtesy of service personnel, ease of doing business, accuracy of billing, experience and knowledge, etc.

However, if takes too long for the FSE to resolve the problem or if the Field Service Engineer (FSE) needs to return because they didn’t fix the problem right the first time, the customer will be unhappy. If this remains a persistent problem, Customer loyalty and retention will suffer.

To prevent this problem from occurring, Field Service Organizations (FSOs) must be aware the bottlenecks, or, barriers, which prevent their FSEs from providing excellent speed of service and first time fix rates. For example, technicians may have:

• Insufficient knowledge to address the issue at hand: For example, they may lack the skills to solve the problem right the first which can result in either a repeat visit or the need to dispatch a different FSE to the customer site, thus extending the length of the downtime.

• Inaccurate or partial data about customers and/or products: FSEs must spend additional time onsite attempting to understand the customer’s problem when this type of situation occurs. Not only do run the risk of making inaccurate repairs when they rely on inaccurate or partial data, they also run the risk of impacting the quality of future repair if they do capture complete or accurate data.

• Inability to communicate effectively with remote experts: This can happen when the remote support expert is not able to understand or visualize the issue described by the FSE and/or when the FSE doesn’t understand the corrective action suggested by the remote experts.

• Inaccurate spare parts inventory - Service visits are closed incomplete or extended when this FSE doesn’t have the right part on hand.

• Non-existent audit trails to track previous service requests or warranty information - This means that FSEs lack the right information to properly troubleshoot, diagnose, and repair the problem. Not only does it increase the chance of a repeat service visits, it results in a situation where the FSO may not be meeting their contractual obligations or providing more service then the customer is entitled to; both have consequences.

Given that FSEs spend almost 1/3rd of their time at the customer site, OEMs must do anything they can to help FSEs avoid these bottlenecks. To ensure FSE optimize the customer experience, companies can turn to several solutions, including:

• Utilizing online forms to capturing critical service information

• Providing FSE with online access to Knowledge resources

• Improving parts availability through catalogs and inventory tracking apps

• Offering remote support to guide technicians to make better diagnostic and repair decisions

• Maximizing customer lifetime value through instant quotes and contracts

All these solutions are currently through commercially available, end-to-end field service management Solutions.

Benchmark research by Field Service Insights indicates that these types of solutions have a measurable impact on improving Key Performance Indicators (KPIs) related to field service. For example, companies who implement these solutions can increase FSE utilization and calls completed per day by 25% and 30% and reduce service resolution time and calls requiring second level support by 56% and 64%, respectively.

These improvements validate the tremendous impact that field service applications, such as those described above, have on enabling FSEs to deliver a better Customer Experience.

Michael Blumberg is Founder and Executive Director of Field Service Insights and CMO of Mize, Inc. Deliver

May 23, 2019 • Features • future of field service • Millenialls • millennial • MIllennials • Field Technologies

In the endless talk about the shift from the retiring baby-boomer workforce and the incoming Millennials, I as a representative of that overlooked, unforgotten middle child, poor old Generation X, would like to just take a moment to point out that we often tend to get left out of the conversation. Now, don’t worry, this isn’t going to be an article of self-pity - that’s just not the way us Gen-X folk roll.

Nope, we are the generation that just rolls our sleeves up and gets on with it.

Unlike our Baby Boomer parents and elder siblings, who were able to indulge in free love whilst turning on, tuning in and dropping out, that greatest consumer generation of them all, who spent every dollar they earned as they lived solely in the now, those of us in Gen X, got up off our backsides and went and got a McJob to see us through college before generally fixing the ‘Boomers mess and creating the easy gig that the Millennials got to inherit.

You know sometimes history can be a cruel mother to the middle child.

The Millennials are the first generation to exist in a time of huge technological advancement (and it’s subsequent impact on society) since the industrial revolution. Therefore, quite rightly, we should factor in such significant change when considering how we attract, develop and retain them within the workforce. All I ask, is just occasionally, spare a thought for us poor oft overlooked Gen Xers who have been quietly making things tick over for a long time now.

I mean, OK they might be the first google native generation, and the internet as we know it today may have been invented by a ‘Boomer, but it was us who terraformed the world wide web from the frontier town of the early nineties to the sprawling global metropolis it is today. You’re very welcome.

All of the above is of course said firmly with my tongue in cheek. Crikey, technically, I’m actually dangerously close to being a Millennial myself having been born in ‘80 - technically I think that makes me a Xennial - meaning I’m more down with the kids than my elder Gen X brethren, but still remember the sheer agony of pre-app dating, and the terrifying wait on the phone to see if it was your intended date who picked up, or her rather more hostile father.

And whilst, it is of course fun to pick on both ‘Boomers and Millennials alike from my lofty Gen X pedestal, there is a actually a serious point to be considered here.

Sure, there are plenty of things that we should be considering when the difference from one outgoing generation to the incoming generation within a workforce is so pronounced. I know, I’ve certainly spent plenty of time writing and talking about the topic in the past.

For example, ‘Boomers wear the knowledge they have earned through study and experience like armour. The deeper the knowledge, the stronger the armour - as the more invaluable they become to an organisation.

Millennials on the other hand, see knowledge as an easily accessible resource, always readily available and on demand through a couple of taps and swipes on the phone in their pocket.

"They are the first generation to exist in a time of technological advancement since the industrial revolution..."

‘Boomers viewed career paths as fairly straightforward, linear progressions. A ladder to be climbed, with progress being in steady increments, one rung at a time. Millennials, are as inclined to move sideways, often into a different industry entirely, and research by Deloitte showed the average time a millennial intends to stay in a job is just two years.

Another huge difference is that whilst financial remuneration always played a key role in ‘Boomers career aspirations, Millennials value the societal impact of a company and will look at soft factors like company policies on diversity, inclusion and flexibility, equally if not more so, than just money itself.

So yes, there undoubted differences between the two. And yes to reiterate such changes should be considered when talking about talent recruitment, retention and development. However, it feels to me that if we reassess things to radically within our internal procedures, we may be at risk of losing what I believe is the utmost important thing for any business to maintain if they want to be successful. An Inside-Out perspective.

Remember, as much as Millennials are our new/future workforce, they are also our new/future customer base.

It is obviously thus, highly important to acknowledge what makes this generation on the whole, buy into a brand - green carbon neutral policies for example carry as much wait in this age, as a cheesy celebratory endorsement would have back in the 80s. In doing so, and by being a company whose values Millennials can buy into, you will enhance your recruitment success. But one caveat here is it needs to be led from the top and be genuine.

Millenials have an inate ability to smell BS from distance.

The other issue I see with sweeping generalisations of a generation, is that by treating Millennials as a monolith, we may be at risk of overlooking the individual - and in field service in particular, the individual is often the star of the show.

This creates something of a duality that we must overcome and I suggest doing so by adopting a two pronged approach to our workforce. On one hand we need to acknowledge and embrace that many of the Millennials that come through the workforce may be just ‘passing through’ and invest in the technologies such as AR and knowledge banks, technologies which can make them as productive as possible, as quickly as possible. Here, we want a workforce with a shallow but broad skill set that can then be supplemented via remote assistance by experts with deeper knowledge when neccessary.

Simultaneously, we need to identify a number of career paths that enable those individuals who buck the trend of being part of a transitory workforce (and beyond the hyperbole there are many out there believe me) to grow within your company. Tap into the gamification instincts that are almost embedded in the root directory of Millennials by attaching gravitas, kudos and continual learning to roles where deep experience is built upon.

Ideally, such a two-tiered structure will ultimately allow you to utilise the emerging gig economy or contingent labour sectors - giving you flexibility within your staffing that could potentially be a major benefit to your P&L. A win-win all round. Alternatively, you could just ride it all out until the Gen Z cavalry arrives to quietly save the day just like us Gen Xers did for the ‘Boomers.

May 23, 2019 • video • Features • Astea • Kris Oldland • manufacturing • Video • field service • Internet of Things • IoT • Servitization • John Hunt

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply