Having given an excellent presentation in the Field Service News Digital Symposium on the application of Artificial Intelligence in service triage, Mark Hessinger, Vice President, Global Customer Service, 3D Systems Corporation spoke with Kris...

ARCHIVE FOR THE ‘3d-printing’ CATEGORY

Aug 27, 2020 • Features • 3D printing • Artificial intelligence • Video • Aquant • Parts Pricing and Logistics • north america • Field Service News Digital Symposium • 3D Systems Corporation

Having given an excellent presentation in the Field Service News Digital Symposium on the application of Artificial Intelligence in service triage, Mark Hessinger, Vice President, Global Customer Service, 3D Systems Corporation spoke with Kris Oldland, Editor-in-Chief, Field Service News at length about the Aquant solution that they had implemented.

The session was designed to shine a light on the many benefits that 3D Systems Corporation realised from implementing the Aquant AI tool. However, it was also a golden opportunity to explore the potential of 3D printing in the service supply chain - which the two discussed briefly towards the latter part of the conversation.

During his presentation, Hessinger outlined that companies are beginning to move away from seeing 3D printing as a tool for prototyping and moving towards using the technology more in production as well.

Given the recent pandemic where supply chains were put under massive pressure as borders came crashing down, could it be that we'll see a further shift towards 3D printing and use of spare parts within the manufacturing sector and beyond?

"The thing about 3D printing is that it is not just making the same things differently. It enables you to do things a lot differently..."

"Yes, with what has happened throughout 2020, and supply chains being interrupted, we do see businesses especially manufacturing sites rethinking their supply chain, how they can do things and using 3D printing is going to really be something that these companies are looking at.

"We are starting to see that feedback already. There was one of the large UK companies just came out with 30% of their new products have to be produced through additive manufacturing.

"Also, the thing about 3D printing is that it is not just making the same things differently. It enables you to do things a lot differently. That bracket I showed [during the presentation] combined 13 parts. Fuel nozzles can be created much more efficiently because you can create geometries that you could never do in traditional manufacturing. I think we're going to have the impact from both sides. Supply chains need to rethink how they build things, and engineering needs to continue to get creative on how they make things to have better quality."

Further Reading:

- Read more about Digital Transformation @ www.fieldservicenews.com/blog/tag/digital-transformation

- Read more about Artificial Intelligence @ www.fieldservicenews.com/hs-search-results?term=Artificial+intelligence

- Read more exclusive FSN news and features from the Aquant team @ www.fieldservicenews.com/hs-search-results?term=Aquant

- Connect with Mark Hessinger on LinkedIN @ https://www.linkedin.com/in/markhessinger/

- Find out more about Aquant's AI-powered service triage @ www.aquant.io/

- Follow Aquant on Twitter @ twitter.com/Aquant_io

Jun 12, 2020 • Features • 3D printing • Augmented Reality • Digital Transformation • Parts Pricing and Logistics • worldwide

Covid-19 has changed the world, Service leaders have to look beyond "business as usual" and find new ways to operate. Developing new solutions, delivered via strong leadership, is key to continuity. Bill Pollock explains...

Covid-19 has changed the world, Service leaders have to look beyond "business as usual" and find new ways to operate. Developing new solutions, delivered via strong leadership, is key to continuity. Bill Pollock explains...

While many would argue that a serious marketing and business development action plan is required at all times, this is especially true during turbulent times. During historical boom economic growth periods, post-war recoveries and peacetime economic expansions, it seemed that virtually any half-hearted marketing or business development activities led to continuing business growth.

However, when the going gets rough, there are two key factors that all services organisations must keep in mind:

- Life – and business – still go on, but

- Customers have neither the time nor the inclination to mess around.

Field Service Strategy During and Post-Pandemic

The compound events of the sudden and unexpected spread of the Coronavirus, and the subsequent crash of the global economic markets have temporarily brought the world, and its businesses, to a stunned and sudden standstill. There is no longer “business (or life) as usual”. Many citizens are now “sheltered at home”, either voluntarily, or mandated by their respective governments. There is also an increasing realisation that life as we knew it would no longer be the same. As a result, neither would field services – nor services of any kind!

Already, there are many facets of the traditional services delivery model that have changed forever. However, workers will continue to use their computers, tablets and smartphones to get their day-to-day jobs done. The mobile workforce will become increasingly mobile – as will the pre-Coronavirus office workforce. As such, networks and carriers will become even more important components of the customer and field technician communications processes than ever before.

Payments will still need to be made, although there are likely to be less ATM transactions, as they will likely be replaced by an increase in online payments via the Internet, Apple Pay, PayPal, Venmo and the like. Chipped credit and debit cards were supposed to slowly replace the older magnetic strip cards; however, this transformation has been accelerated by the Coronavirus pandemic, where more and more payments will now be made via “tap” or “wave”, instead of swipe, insert or hand-to-hand transfers of cards or cash with human clerks.

Patients will still go for MRIs, CT-scans and surgical procedures – but, at least temporarily, not so much for elective surgeries or non-life-threatening medical situations. Milk will still be processed. Pharmaceuticals will be manufactured. Textiles will be sewn. And services organisations will still be called upon to support their customers, dealers and end users with a full array of new and steadily evolving services.

When you think about it, everything that we do in the services industry still needs to get done – especially in these turbulent times. In many ways, we are all doing the same things as we did pre-Coronavirus – although now, there is an extra measure of importance in everything we do, every step we take, and every customer we support. It’s just going to be different! And remain different!

"This may also be a good time to strengthen your own organisation’s relationships amongst its strategic partners..."

As recently as just a few months ago, undoubtedly, we were all dealing with customers (or vendors) who, for whatever reasons, simply strove to meet “acceptable” levels of service delivery performance and customer satisfaction. Some had internal goals, objectives or mandates that needed to be met; while others simply wanted to improve existing levels of customer satisfaction to “keep up with the Joneses”. Now, everything is different. The stakes are suddenly higher.

Every business, everywhere in the civilized world, now requires the highest levels of B2B (and, increasingly, B2C) support from its cadre of vendors and partners – no matter whether the support required is on-site break/fix, helpdesk or preventive maintenance; or systems integration, consulting or professional services. However, increasingly, there has been (and is now virtually mandated) a rapidly-moving transformation away from the traditional on-site, “hands-on” approach (whether supported by Augmented Reality or not) to a “hands off” approach where service and support is, instead, provided via Predictive Diagnostics, Remote Diagnostics/Maintenance, and now – Remote Expertise.

3D Printing within the Field Service Supply Chain?

Further, “last year’s technologies”, such as 3D Printing, have been propelled directly into the forefront of Parts & Inventory Management as global businesses have relied heavily on the ad hoc ability to manufacture parts – on-site, and immediately – to support local medical and related emergencies. Most analysts agree that 3D Printing will fast become a mainstay of parts and inventory management as quality continues to improve and costs come down further.

In today’s tense environment when an unforeseen development can bring air travel and mail service to a sudden halt, thereby stopping parts shipments or freezing deliveries; send unexpectedly high numbers of people to medical centers for tests, evaluation and possible hospitalisation; or disrupt field service operations as otherwise would-be mobile workers sit “sheltered at home” until they are permitted, once again, to make service calls on-site, there is a renewed need for services “above and beyond the call of duty” to support what used to be “business as usual”.

But how can this be done?

Quite simply, it will involve ramping up the types of services and support products that have been historically marketed to a higher level of contingency-based support as well. This may also be a good time to strengthen your own organisation’s relationships amongst its strategic partners. For example, whatever your company’s portfolio of service and support products may have been historically, now would be a propitious time to refocus it around professional services including contingency planning, business continuity and disaster recovery, etc. And, if you already provide these types of services yourself, now is the time to promote them more heavily to the marketplace. However, if you don’t – now may be the right time to find yourself a strategic partner in those fields with which to “piggyback”, or joint market, your services.

"Whatever happens from this point on, the world has changed..."

Customers, who only a few months ago, were primarily concerned with hardware, software and helpdesk support, are now also talking about contingency planning, business continuity and disaster recovery. Terms like “high availability” and “hot sites” have been around, it seems, almost forever. However, with the advent and proliferation of the Coronavirus pandemic, they are now “top of mind” for many businesses, and no longer on the “back burner”. Are these the types of professional services that are also “top of mind” to the marketplace when they think of your organisation? If not, what can you do to make it so?

The Critical Rise of Augmented Reality

Field service solution providers that did not offer an Augmented Reality (AR) or Merged Reality (MR) component to their respective portfolio of offerings yesterday, were still credible alternatives for supporting your organisation’s field operations – but, not any longer! If your services organisation is looking for a credible FSM solution today, you should only be considering those powered by the Internet of Things (IoT), and built on a foundation of AR/MR, Artificial Intelligence (AI) and Machine Learning.

However, AR/MR is mostly helpful for empowering on-site field technicians to perform the “fix” quicker, without mistakes, and without the need to carry pounds of paper or electronic schematics with them as they drive to the customer site – but they still need to drive to the customer site! Although an AR/MR solution is essentially resident in the Cloud, it still requires “feet on the street”!

One alternative would be to train the customer/user to AR/MR to perform the “fix” themselves – but this reflects an age-old conundrum as to how much power do you want to give to the customer? How much can they be trusted to make the “fix” correctly, and without damaging anything, or taking the equipment out of warranty? What about regulatory requirements, particularly in the medical/healthcare and other highly-regulated industry segments? There will need to be an orderly progression to allow some – but not all – customers to add this capability to their self-help capabilities. This is where Remote Expertise can be of great value, incorporating such features as a “virtual” technician on-screen presence, repair instructions shown via superimposed human hands, and on-screen telestration (i.e., similar to a sports commentator’s on-screen annotations during a football match, etc.).

Whatever happens from this point on, the world has changed. The way of conducting business has also changed; however, the way of supporting businesses with the services and support they require to satisfy their customers has not – it just got a lot more complicated, and, perhaps, a bit more serious. With this increased seriousness, we can “kiss goodbye” all those meaningless and frivolous attempts to “bundle” our existing services products into a “new” branded package, or otherwise try to disguise our “same old, same old” offerings by thrusting them into a tiered, or “bullion” packaging portfolio (i.e., Platinum, Gold, Silver, Bronze, etc. – that would be so 1990’s). Our customers have always been too smart for that anyway!

What the market wants – and needs – is an honest and forthright offering of service and support that will give them one less thing to worry about as they attempt to meet their immediate struggles, and their customers’ quickly evolving needs in this “new” – and very different – world.

Turbulent times require a serious approach, plus serious marketing and promotion – and it doesn’t get much more turbulent than this! We owe it to our customers, ourselves and our respective communities to rise to the occasion, and ensure that we can provide the services and support that our customers require immediately, as well as in the short-, mid- and longer-term. Services marketing and business development have never been more serious.

Further Reading:

- Read more articles by Bill Pollock @ www.fieldservicenews.com/billpollock

- Read more about Covid-19 in service @ www.fieldservicenews.com/en-gb/covid-19

- Read more about Digital Transformation in field service @ www.fieldservicenews.com/digital-transformation

- Read more about 3D printing in service @ www.fieldservicenews.com/3d+printing

- Read more from Bill Pollock's own blog @ https://pollockonservice.com

Apr 20, 2020 • Features • 3D printing • copperberg • manufacturing • Additive Manufacturing

Additive Manufacturing (AM) is on the front line of the unfolding industrial revolution. This string of rapid prototyping technologies is replacing conventional production, and consequently, it is poised to generate substantial economic revenue by...

Additive Manufacturing (AM) is on the front line of the unfolding industrial revolution. This string of rapid prototyping technologies is replacing conventional production, and consequently, it is poised to generate substantial economic revenue by 2035—$196.8 billion. Adrian Cirlig and Teodora Gaici explain more...

The future is certainly bright, but so is the present. On any given day, manufacturers can turn to AM technology to facilitate the production of individually customized products at relatively low costs, reshape the design process, and consolidate their supply chains.

AM will remain a particularly active architect of customer-driven design, virtual inventory, and rapid iterationsfor new product development. Yet it’s not all roses; the lack of quality consistency may slow production runs to a trickle.

In consequence, is AM both the cure and the culprit of innovation volatility? Industry experts seem undecided in the matter as this paper from the Rand Corporation outlines.

Additive Manufacturing: A Magic Bullet for Field Service Logistics?

AM is, after all, a disruptive technology—one that comes with a learning curve. Many top-tier leaders have justifiably gauged the trajectory of additive technology, and when they sensed it had promise, they gingerly lunged for it.

Through the use of AM technologies,anyone can manufacture products without any required tooling for production. That’s right—traditional molding techniques or large machines that have yet to be deftly transported will no longer impede manufacturing performance. Simply put, this set of powerful AM machines has the ability to fabricate a product from a digital geometry representation. Once they accurately replicate computer-aided design drawings, AM tools directly transform three-dimensional structures into functional physical prototypes and, more recently, ready-for-use products—all that in just a matter of minutes. The physical parts are built out of plastics, polymers, metals, ceramics, stainless steel, or other types of material by using a layer-by-layer printing process. A vast majority of modern AM machines print with multiple materials simultaneously and allow the development of mixed-material products.

"Manufacturers must have a plan for everything—how, when, and where they design and manufacture products rank top of the list..."

Organisations with a strong innovative culture recognize the need to facilitate on-demand production, and as it turns out, they’re growing faster and increasingly outpace their competitors.

Innovation, however, is rarely linear. In most cases, it’s a progressive affair that disrupts practically every aspect of the business

Manufacturers must have a plan for everything—how, when, and where they design and manufacture products rank top of the list. AM is already distorting modern-day manufacturers’ long-planned reality by encouraging them to rethink every design-to-fabrication procedure and go well beyond traditional manufacturing methods. Those who are up to the challenge will become the leading innovators in their market.

Additive Opportunities for the Taking

The revolutionary AM technology is becoming commonplace one layer at a time.

This significant surge in popularity may be due to the proposed benefits that are in visible contrast with those provided by conventional manufacturing operations.

Milling, for example, can produce a large amount of unnecessary material waste. Distinct in nature, additive processes have become a statement of sustainability—both economically and environmentally. It is touted that AM technology reduces energy consumption, facilitates dematerialisation, and improves resource efficiency by using waste as an input to construct equitably personalised products in a cost-effective manner.

This type of manufacturing process also attempts to minimise the need for packaging, transportation, and storage. More than that, prototyping and building a high-value product from geometrically complex data in-house can also significantly reduce shipping costs and shorten supply chains.

Since AM machines offer complete (and highly flexible) design freedom, they allow early customer involvement in the product development process. This customer-driven design procedure helps manufacturers respond to individually customised demand wherever needed, revise and conduct timely design changes, and reduce time-to-market. Above all, manufacturers are empowered to forge direct-to-consumer relationships and prolong the lifetime value of a specific object.

"With large-scale printers being well underway, Additive Manufacturing technology will steadily extend its capabilities..."

It’s impressive, but that’s just barely scratching the surface. AM is an advocate of product differentiation—at scale!—and industry experts can take full advantage of this technology to mass-produce custom-fit objects without paying a steep price for additional workers or tooling. Manufacturing in large volumes will, in fact, reduce the cost per unit, minimise the total cost of ownership, and drive greater growth.

At the moment, AM machines can mainly print tiny (yet rather complex) items; they can briskly produce fully-functional parts in just a single production step and without the need for assembly lines. With large-scale printers being well underway, AM technology will steadily extend its capabilities to open up innovative business models across the industry.

Additive Manufacturing Technology Is Ripe for Investment, But the Caveats Remain

It’s in the cards: AM tools will offer unlimited design-to-fabrication opportunities for modern-day manufacturers. The vast majority of these professionals may inevitably face certain drawbacks that can’t (and most probably won’t!) go unnoticed.

Quality consistency is one of the main stumbling blocks.

Every manufacturer aims to develop consistent parts and ensure repeatable quality levels throughout their production lines. Yet no two items are exactly the same. Given that AM machines can produce parts as small as 500 nanometers, the differences may be slim or less obvious; but they exist, and a single inconsistent subset that is left unaddressed could put the brakes on the production line.

All the materials used for crafting AM-produced components should also be processed within the required quality standards and specifications, or else they might prevent objects from being recycled

"Many manufacturing and field service professionals haven’t gained an in-depth understanding of Additive Manufacturing techniques yet, let alone hands-on experience.."

The knowledge gap is another considerable barrier to the adoption of AM technology. As this study warns “[the] knowledge of AM in the industry exists in pockets.” Many manufacturing and field service professionals haven’t gained an in-depth understanding of AM techniques yet, let alone hands-on experience.

Amid global economic unrest, the lack of know-how may drive economic insecurity and hamper technology adoption.

Route Around the Gaps and Fortify Additive Manufacturing Innovation

An AM-produced component may be a sure bet for unprecedented manufacturing gains. That is, of course, if manufacturers do not band-aid the inevitable caveats that eagerly come with every disruptive technology. /p>

As AM technology advances, the trick is to promptly address each limitation or potential risk and transform every temporary hiccup into an opportunity for modernisng manufacturing lines.

Capturing AM’s transformative potential is crucial for manufacturers who want to advance customer-led product development and freely reach all their revenue growth targets.

Further Reading:

Adrian is the Editor for a series of key industry events with Swedish Conference Producer, Copperberg.

- Find out more about his forthcoming event the Field Service Forum @ https://www.copperberg.com/fieldserviceforum/

Nov 29, 2019 • Features • 3D printing • Martin Summerhayes • Nick Frank • The Service Community • BSI

Mark Glover sat in on the latest Service Community event where the agenda covered 3D printing, data-driven manufacturing and PAS 280, the beginnings of a British standard for life-cycle engineering services.

Mark Glover sat in on the latest Service Community event where the agenda covered 3D printing, data-driven manufacturing and PAS 280, the beginnings of a British standard for life-cycle engineering services.

Nov 15, 2019 • Features • 3D printing • future of field service • Additive Manufacturing

Mike Shields, Technical Director at DMS Systems Ltd and Centrex Print Services brings us an in depth look at the potential power of 3D printing across multiple sectors...

Mike Shields, Technical Director at DMS Systems Ltd and Centrex Print Services brings us an in depth look at the potential power of 3D printing across multiple sectors...

Jun 06, 2019 • Features • 3D printing • future of field service • Parts Pricing and Logistics

How do you deliver the right part, at the right time and at the right price? If you work in supply chain management, then you’ve probably seen and wrestled with these questions. Historically, the spare part transaction was a simple one: a customer needed a component that had failed, they phoned up the company, ordered and paid for the part. Transaction complete.

However, the sector’s shift to a servitization model rather than the traditional transactional-based framework has seen many companies cut their losses and cannibilise their components to align with SLAs.

In the era of servitization, the cost associated with asset failure is having a substantial impact on balance sheets. Income from replacement part sales is now considerably less than the loss accrued from downtime. The priority now is to get an asset back running as quickly as possible and if parts are struck out in the process, then so be it; the numbers will eventually balance out.

It means that a cost-plus approach to spare-parts is losing validity.

The price of producing a part and adding the profit on top is being usurped by a more value-based approach - that is, a cost based on the ultimate value to the customer. Or as a firm enters another vertical – as is common in service – will they align with a different approach such as a market-based strategy?

In short, making money from selling parts is no longer the revenue stream it once was. As well as modifying itself to the shifting nature of the sector it serves, spare parts must contend with other factors that are disrupting the transactional sphere it has felt so comfortable operating in such as E-commerce and 3D Printing.

E-commerce, for example, works best in a market-based strategy. Here it can snuggle up to China, where parts are getting cheaper and the quality is getting better and provide credible components. Add to this the threat of online retailers such as Amazon entering the market and the future does look rather bleak. Meanwhile, looking hungrily into the arena, biding its time and waiting for the right moment, 3D printing could be the most disruptive threat to traditional supply chain management.

Also referred to as additive manufacturing, the ability to print components could quash the issue of time-affected delivery. Atanu Chaudhuri is Associate Professor of Operations and Supply Chain Management at Aalborg University and an expert in additive manufacturing and 3D Printing.

As a recent guest on The Field Service Podcast he told me that some industries have been quick to embrace the technology while others less so. “The forerunners of the adoption of these technologies have been the aerospace and automotive sectors,” he said. “However, there are a lot of other industrial manufacturers who are exploring this but are at different stages of adoption.”

Extolling its financial virtues, Chaudhuri affirmed why 3D printing is aligned with servitization and suggests those taking the long-view of the technology will see a positive return on investment. “If you take a more life cycle perspective,” he said, “and look beyond the cost on a part-to-part comparison or look at the usage of the part over a lifetime of the product, say 15 or twenty years, suddenly you will see a huge difference. You will not be having a lot of inventory, you reduce the inventory carrying costs and maybe the environment will benefit, you will use fewer materials and suddenly the business case looks much better.”

Another challenge the sector continues to face is counterfeit parts. Non-genuine components can compromise safety, the integrity of finished goods and bring reputational damage. It’s an issue that Chris Mitchell, Business Transformation Director at Software and Services company PTC, is all too aware of. He references outcome-based models as a contributing factor to the problem as firms try to gain an advantage in the market. “With industries becoming more service-orientated and more competitive, this issue of counterfeit parts from China, Turkey and other parts of the world creeps up more and more,” he says.

"Making money from selling parts is no longer the revenue stream it once was..."

OEMs spend heavily on research ensuring the quality of their parts, utilising specialist software to engineered products in the best possible way, making the components safe and durable. It’s the finances associated with asset upkeep that forces some firms to opt for a damaging short-cut. “When looking at the cost of individual repair or maintenance event, cost pressures and short-sightedness often lead to the wrong buying decision whereby the cheap counterfeit part is used,” Mitchell explains.

Storage and warehouse logistics remain a puzzle for firms. It’s commonplace to have one centralised hub where all stock is housed making it simpler for inventory management; while a collection of smaller, local warehouses allow for greater flexibility in regards to geographical logistics but requires careful management. Taking advantage of the malaise, initiatives around smart-IoT connected storage boxes, such as those offered by BT and ByBox are proving solutions to the logistics issue.

Strategically placed parts can be collected by engineers who through cloud-based software, can check where the nearest part to them might be. The very nature of field service is also having an affect on how firms place themselves in the sector. By this, I refer to the many verticals that service operates in. It means requirements round spare parts can differ from the medical sector, for example, which will have different behaviours and expectations than, say, the oil and gas market.

This has led to companies segmenting logistics depending on their customer silos. To elaborate, one industry may require a very rapid solution, so expectations will centre on availability and quick delivery meaning the provider’s logistic channel needs to be flexible enough to meet these expectations. Conversely, another industry could be more demanding of uptime and be more price sensitive when purchasing components. Unfortunately, there remains another factor that now firms can do very little about.

At the time of writing uncertainty with Brexit continues and urgent questions round its effect on the global supply chain remain unanswered. While the knock-on effect of political decisions remains out of our hands for now, perhaps it’s time to ask a question that we may have more control over. Will the transactional model disappear completely?

Going forward, I think there will be a place for all approaches and here the diversity of markets could be an advantage. There will always be customers who want to deal on a transactional basis. SKF and GE Healthcare for example, still have long-term contracts with clients who prefer to deal in this way. These are large multi-national corporations and their continued loyalty to traditional frameworks should offer encouragement to other firms.

Spare parts and supply chain management is broad enough to accommodate and embrace change, be it new technology, political uncertainty and a shift in customer buying habits. One far-reaching question however will always remain: How do you deliver the right part, at the right time and at the right price? Amidst the changing sands of supply chain management, it’s something we should continue to ask and also take comfort from.

Jun 04, 2019 • Features • 3D printing • manufacturing • Additive Manufacturing • Parts Pricing and Logistics

An industrial products manufacturer has a large portfolio of spare parts in its portfolio. It has 10 year service contract with its customers implying that the company must be able to deliver spare parts on time for 10 years to its customers even though the product may longer be produced. Thus, the company has to maintain inventory of some of those spare parts. Such inventory costs run into millions of dollars. Many of those spare parts are produced by suppliers. Demand for those spare parts are low and unpredictable.

On Monday morning, the spare parts manager received a call from a customer in another continent “ Mr. Paul, our equipment is out of action as it cannot be started in the morning shift. My maintenance guys confirmed we need to replace a part, supplied by you and we do not have it in inventory. I am sending you the part number. Please deliver it within three days otherwise there will be heavy loss.” Mr. Paul checked the part number in the ERP and found that they also do not have in stock.

He found out who the supplier is and called him up. The supplier replied saying that they cannot make only one piece. They will need an order size of at least 20 and it will take 1 week. What will Mr. Paul do? He remembered that the Vice President (VP) of Supply Chain was talking about 3D Printing of spare parts in the last meeting. Can the part be printed? How will Mr. Paul figure that out?

He refers to the presentation by VP- Supply Chain and finds the name of a company called 3D Hubs (UPDATE: 3D Hubs is now Hubs). Mr. Paul checks out the website of 3D Hubs and found that he can upload the drawing of the parts and get an analysis for printability along with a quote. He uploaded the drawing, got the quote for delivery within three days and went to his boss.

His boss, Mr. James said “Are you crazy? How will I be able to justify that price? Also, have you noticed that they are not printing our part using our specified material? This will never work.” Mr. Paul tried to argue “This is a very strategic customer for us. If they are not satisfied and cancel the service contract, it will be a big trouble for us. We can say that they can run their equipment with it until an actual replacement spare part is produced and delivered by the supplier. I can talk to R&D about the approval for the deviation in material. It doesn’t seem to be a big change.” Mr. James said “You are taking a big risk, Paul. If you want to try, go ahead.”

In the end, everything turned out well. That part was produced using additive manufacturing (AM) and delivered on time. Paul received appreciation for his efforts. VP- Supply Chain was very happy and said to Paul. “Now, I want to evaluate our entire spare part portfolio and develop a systematic process of evaluating which of those parts can be printed and which cannot. It will be great if you can evaluate our portfolio and present in our next month’s meeting.”

Paul has 10 years of experience in spare parts but he does not know much about 3D Printing. How can we help Paul? I am sure that there are many people like Paul in large industrial manufacturers, who need similar help. Lets try to outline a steps-by-step process for selecting spare parts suitable for additive manufacturing.

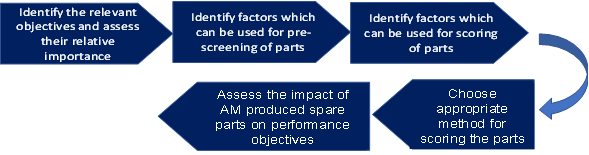

Step 1: Identify the objectives

Some potential objectives for producing spare parts using AM can be:

• Supply risk reduction;

• Lead time reduction;

• Inventory cost reduction;

• Ensuring local content;

• Minimizing loss of production;

• Reducing carbon foot print across life cycle.

Companies can decide the most relevant ones from those and provide relative importance of those using a method called analytic hierarchy process. Instead of directly assigning importance weights to each objective, experts within the company can make pairwise comparison of the objectives using a scale (for example 1-3-5-7-9) and derive the importance weights.

Step 2: Identify the factors to be used for screening the spare parts for AM suitability

Some factors, which can be used for screening the spare parts for AM suitability can be as follows: It is important to note that the company should have data on the following factors to be considered for screening.

If such data is not available or available in different IT systems or in physical form ( i.e. drawings with dimensions and material specifications), it will be difficult to include those at the screening stage.

1)Demand and demand uncertainty of the parts

Parts with low and uncertain demand are more suitable for spare parts

2) Overall part size

(Part must fit build volume of the equipment) As the equipment for different AM technologies have build size restrictions, part-size is usually a restriction, if it cannot be fitted in the build chamber. Sometimes changing the orientation of the part may be needed to fit it into the build chamber, but it might require additional support structures and may increase the overall production time. Decisions about part orientation in the build chamber can be taken only for the selected parts and not at this stage. The company can specify the upper limit of size or a range of sizes of parts, which they would like to consider

3) Materials

Not every material can be printed. Thus, parts whose specified materials can be printed can be screened when a company is starting on its journey of producing spare parts using AM. Later, alternate materials which closely match the specifications can be explored.

4) Supply lead time

Parts with long supplier lead time for conventional manufacturing can be more suitable for producing using AM as overall lead time can be reduced. A company may decide to specify either the lower limit or range of lead time, which they would like to consider.

5) Purchase price or unit cost

High priced parts, in general, can be suitable for AM but some high valued parts may be infeasible because of their size or materials etc.

6) Value of inventory across all locations

Usually parts with high inventory value can be good candidates to be produced using AM. High value of inventory can be due to high number of parts in stock or due to high prices. Sometimes, if a lot of stock is available, a company may decide not to proceed with producing such a part using AM. Some other company may decide that they would like to get rid of that stock and hence it may be worth producing those using AM. A company may also decide to include either price or inventory value as a screening factor.

Figure 1: Step-by-step approach for selecting spare parts suitable for AM

Step 3: Identify the factors to be used for scoring the spare parts for AM suitability

Some potential factors for scoring spare parts in terms of their suitability for AM can be as follows:

• Lead-time;

• Unit cost;

• Criticality in terms of influence of the part for equipment shutdown;

• Demand predictability measured as standard deviation of demand;

• Supply risk in terms of number of suppliers;

• Minimum order quantity.

The screened parts can be scored based on the above factors and how the factors are related to the objectives. Parts with long lead time, high cost, high criticality, low demand predictability, high supply risk and high minimum order quantity in the existing manufacturing process will be more suitable for AM.

Step 4: Choose appropriate method for scoring the parts

There can be multiple approaches to score the spare parts in terms of suitability to be produced using AM.

We mention some basic guidelines below:

1. Multi-criteria decision making approach (MCDM) –scoring parts on factors and linking factors to be objectives (suitable for less number of factors and less number of parts).

2. Logic decision diagrams, cluster analysis and fuzzy inference system (suitable for large number of parts, medium number of factors but strong interrelationships of factors and objectives). If the factors are dependent on each other and how they influence the objectives depends on the levels of the factors i.e. low, medium and high, logic decision diagrams can be built to score a part using different decision rules. In terms of disagreement between experts about the relationships, the relationships can be expressed as fuzzy numbers and fuzzy inference system can be used to score the parts.

3. Cluster analysis and MCDM approach for ranking of part clusters and within cluster ranking of parts (large number of diverse parts, limited to medium number of factors and independence of factors) If the factors considered are independent but the spare parts portfolio is very diverse, it will be necessary to cluster the parts, rank the clusters and then rank the parts within the clusters.

4. Bottom-up expert driven selection using a questionnaire or selection protocol (no data available or not possible to do quantitative analysis) If no data is available in digital form to score the parts, it is prudent to use the expert judgment of the service personnel or maintenance technicians. But, as those persons may not be aware of AM technologies, it is important to demonstrate to them what is possible using AM through workshops and ask them to suggest spare parts, which they find most difficult to get. Companies can also potentially run internal competitions to identify some spare parts to start with.

Step 5: Assess the impact of AM produced spare parts on performance objectives

Once some spare parts are identified, the next step is to develop business cases for the parts. But, those can be done once the appropriate technologies and equipments are identified. For that purpose, a database of all available AM equipments, the technologies they use, the materials they use, the build chamber of the equipments, the surface finish achievable need to be documented.

For the spare parts which are scored high in terms of their suitability for AM, the most appropriate technologies and equipments can also be shortlisted. Then total-cost of ownership based cost models need to be developed to understand the economic implication of producing the parts using AM. The relevant cists which need to be considered are materials, production, energy, labour as well as the savings in inventory and transportation costs over the lifecycle of usage of the parts for different demand scenarios.

Quotes from different service providers can also be used as a reference for taking the final decision. Once a company has done this exercise and identified a few feasible parts, some machine learning techniques can be used to identify the patterns amongst the most suitable parts so that the process can be automated when new parts are added to the portfolio.

May 01, 2019 • Features • 3D printing • future of field service • Servitization

Claims that 3D printing will disrupt and revolutionise the manufacturing industry of the future, have been made since the early 1990s. For field service, that future is now writes Dr Ahmad Beltagui.

Claims that 3D printing will disrupt and revolutionise the manufacturing industry of the future, have been made since the early 1990s. For field service, that future is now writes Dr Ahmad Beltagui.

Picture this scenario: a field service engineer is called out to repair a grounded aeroplane at a remote airport. He finds the problem, but realises that repairing it will mean waiting a week for spare parts to arrive, when the client needs the plane airborne, so the contract, and perhaps his job, is on the line. Could 3D printing provide a faster solution to the problem? Today, it very likely could.

What is 3D printing?

3D printing – also known as additive manufacturing, additive layer manufacturing, rapid prototyping and rapid manufacturing – is a range of production processes that build parts in layers directly from digital designs, without the need for tooling.

These processes typically use a heat or light source to solidify plastic or metal powder, liquid polymer or plastic filament. They can produce complex geometries in small batches or even one-offs in a variety of materials, from biodegradable plastic to aerospace grade titanium. A digital, flexible future for manufacturing and service 3D printing allows production to be carried out on-demand, which is useful when spare parts are unexpectedly needed. Production in remote locations becomes possible, as NASA demonstrated by printing a wrench on the International Space Station in four hours, from a design sent digitally from Earth. 3D printing allows production of highly customised parts, from hip replacements, to dental implants to ear-phones

It enables consolidation of multiple components into one part, which delivers huge benefits in weight reduction, but also helps to streamline supply chains. For example, an aerospace part that used to be assembled from components delivered by around 20 suppliers is now designed as a single, much lighter, component. The only feasible way of producing this design is additively, rather than cutting and joining in traditional methods. Since it requires no tooling, economies of scale are less relevant, so that producing one-off parts is feasible, as Formula One teams have demonstrated with track-side 3D printers. For all of these reasons, 3D printing gives us a vision of a digital, flexible future for manufacturing and service.

The first patents for 3D printing processes were granted as early as 1986, but in recent years there has been a shift in focus from prototyping to enduse parts. Companies across the world, including IBM and Sony, had experimented, but the pioneering, and still market leading, companies were started by engineers in their spare time – Chuck Hull who invented stereolithography and founded 3D Systems, and Scott Crump, whose fused deposition modelling is the basis of industrial and desktop 3D printers made by Stratasys.

Where did it come from?

For many years 3D printing has been widely used in prototyping and new product development. Indeed, Hull’s invention was based on frustration that prototyping designs took far too long. Research suggests that, while prototyping is still the most common use, more companies are printing components and products for end-use by customers.

Where did it come from?

The first patents for 3D printing processes were granted as early as 1986, but in recent years there has been a shift in focus from prototyping to enduse parts. Companies across the world, including IBM and Sony, had experimented, but the pioneering, and still market leading, companies were started by engineers in their spare time – Chuck Hull, who invented stereolithography and founded 3D Systems, and Scott Crump, whose fused deposition modelling is the basis of industrial and desktop 3D printers made by Stratasys.

For many years 3D printing has been widely used in prototyping and new product development. Indeed, Hull’s invention was based on frustration that prototyping designs took far too long. Research suggests that, while prototyping is still the most common use, more companies are printing components and products for end-use by customers. Substantial improvements can be seen in cost, quality, speed, reliability and materials.

The industrial and commercial viability of 3D printing for volume production is being tested by companies such as General Electric, whose dedicated factories have produced over 30,000 aero-engine fuel nozzles and over 100,000 hip implants. And in some sectors, such as hearing aid production, reports suggest that every company that has not adopted 3D printing has not survived. This is only the start of a growing industry, whose annual revenues are projected to grow to over $20bn.

A growth industry – in services

Following two decades of steady development, there has been rapid growth in 3D printing revenues since around 2010. This is partly helped by the expiry of the first patents, leading to an open-source “maker” movement at the low end, which sees start-ups receiving multi-million dollar kickstarter investments and 3D printers offered for under £500 by supermarket chains, such as Aldi. Estimated global revenues for 3D printing products and services grew from $1bn in 2009 to $2bn in 2012 to over $5bn in 2015, with compound annual growth over 30% over most of this period. 3D Systems and Stratasys, who account for over a fifth of the total, saw their product revenues soar until 2014. However, the last few years have been more challenging for these companies, because the potential of 3D printing has now been recognised by companies from a variety of sectors. Driven by fear of disruption, manufacturing companies including HP, Ricoh, GE and Polaroid, as well as software companies such as Adobe, have entered the market with their own 3D printers. Meanwhile lower price competition from Asian manufacturers has increased competition in 3D Printing. The answer to the competitive challenges, as is so often the case, lies in service and servitization.

Servitization and 3D printing

With a large and growing installed base of 3D printers, there is potential for service providers to offer maintenance and operation related services. As UK based manufacturer Renishaw has reported, customers often buy a 3D printer, only to then ask for someone who knows how to use it. This is because setting up, maintaining and post-processing are highly technical tasks that require skilled personnel. Market leading companies increasingly derive their profits from digital manufacturing services, offering a full range of solutions, including design and production. They offer to take customers’ ideas through a whole digital product development and production process, effectively transforming manufacturing into a service.

So, back to our hero, the field service engineer at the remote airport, trying to fix his grounded aeroplane. In the time it took you to read this article, he could have received or downloaded the digital file for the part he needs and perhaps set up the printer to start making the part. A few hours later, he could come back to collect it and perform any post-processing required, before fitting it and letting the customer get back to business.

How far-fetched is this scenario? How far away are we from this vision of reality? Perhaps not too far. Two main barriers remain. The first is that post-processing and other technical tasks take time, effort and skill. There is, therefore, a need for managers to ensure staff are trained and have the required skills for digital production technologies. The second is intellectual property. While digital file standards make it possible to share designs, the fear that anyone can produce (or modify) a design makes companies reluctant to share.

The last few years have seen hype, unrealistic expectations and subsequent disappointment (news just in: not every home has, or is likely to have a 3D printer). However, technologies are maturing as focus shifts to refining and improving, rather than reinventing.

Global revenues for 3D printing passed $9bn last year, a large and growing proportion of which are service revenues. In short, the time to realise the benefits and take advantage of the demand for 3D printing services is now.

Dr Ahmad Beltagui is from the Advanced Services Group at Aston Business School

Mar 25, 2019 • Features • 3D printing • manufacturing • Parts Pricing and Logistics

Of all the technologies currently vying for the attention of field service professionals, 3D printing is the one that appeals most to the imagination.

Sure, Augmented Reality and Artificial Intelligence are exciting, and the use-case for both is becoming stronger. But how about a printer that prints a tangible, useful component? A spare part that an engineer can produce and integrate while out on a job. What if 3D printers with robot arms were the final part of a first-time fix process, working in tandem with selfmending, machine learning assets?

I say the above with tongue firmly in cheek. I think we’re a long way from a technician-free fixing procedure; in fact, I think the human, engineer element will always be a constant, but you can see why the technology gets the juices flowing.

That said, the concept of 3D printing or additive manufacturing is not as new as we might think and has been in a period of gestation for nearly 40 years. Its first milestone was in 1981 when Dr. Hideo Kodama from the Nagoya Municipal Industrial Research Institute published an account of a working photopolymer rapid prototyping system. A machine that produced photo-hardened materials, corresponding to a cross-slice of a model, that when layered create 3D tangible parts.

Unfortunately, lack of funds meant Doctor Kodomo was unable to pursue his theories but American Charles Hull, in 1984 etched (or printed) his name in history by inventing stereolithography which used digital data to produce the 3D model. Then in the early 90s, the world’s first Selective Lasering Sintering (SLS) machine was invented, which shot out a powder, rather than a liquid, to build a solid (if slightly imperfect) 3D object.

The turn of the millennium saw the medical sector fully embrace 3D printing when over the space of ten years, scientists were able to create a miniature kidney, a prosthetic limb and bio-printed the first blood vessels using only human cells.

But where are we now with the technology and what manufacturing industries are really squeezing out the potential of additive manufacturing?

“We do not have enough people who can design a product for 3D printing..."

“The forerunners of the adoption of these technologies have been the aerospace and automotive sectors,” says Atanu Chaudhuri an Associate Professor of Operations and Supply Chain Management at the University of Aalborg and an expert in additive manufacturing. “However, there are a lot of other industrial manufacturers who are exploring this but are at different stages of adoption.”

I recently recorded a podcast with Atanu, ahead of his presentation at the Spare Parts Business Platform in Stockholm, which focused on the 3D printing of manufactured spare parts. With producers at various stages of integration, I asked what challenges they faced.

“One of the most critical challenges is the lack of skills,” he says. “We do not have enough people who can design a product for 3D printing, who can understand the process and technology. However, I think the companies who have invested in the machines, they have taken a step forward, but it is always a costly investment and there has to be a strong business case.”

The business case is essential when discussing any adoption of technology not just in additive manufacturing but in other young technologies. Boards are keen to see a genuine return on its investment especially when it carries financial risk.

However, in the case of 3D printing, Chaudhuri urges companies to take a long-view. “If a company was to do a one-to-one comparison with existing manufacturing technology, it’s most likely that 3D printing will not be suitable,” he admits.

“But if you take a more life—cycle perspective and look beyond the cost on a part-to-part comparison or look at the usage of the part over a lifetime of the product, say 15 or twenty years, suddenly you will see a huge difference.

“You will not be having a lot of inventory, you reduce the inventory carrying costs and maybe the environment will benefit, you will use fewer materials and suddenly the business case looks much better,” he says.

Atanu is an enthusiastic, yet realistic advocate of the technology and its infrastructure. Alluding to his earlier point of training, he admits that universities can come under scrutiny for not providing enough skilled workers, however when I ask what inspires him to do what he does, he cites his students and the role they will eventually play in the future integration of additive manufacturing as a key influence.

“It’s a motivation for me to train the next generation of engineers, industrial engineers or supply chain professionals who are ready to take on the world of digital manufacturing.

“I get immense satisfaction when my students graduate and get positions at the top companies and I can continue working with them. That is the main motivation I have,” he concludes.

You can listen to the Field Service Podcast with guest Atanu Chaudhuri here.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply