In the second feature from a white paper we recently published in partnership with OverIT, we take a look at what tools are included in the new FSM solutions and how they have evolved from the previous iteration of FSM software that we are currently...

ARCHIVE FOR THE ‘features’ CATEGORY

Dec 14, 2021 • Features • White Paper • OverIT • Covid-19 • Servitization and Advanced Services

In the second feature from a white paper we recently published in partnership with OverIT, we take a look at what tools are included in the new FSM solutions and how they have evolved from the previous iteration of FSM software that we are currently using.

This feature is just one short excerpt from a recent white paper we published in partnership with OverIT.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared withOverIT, sponsor of this premium content, who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Having laid out the case that we are now entering a new era of field service, one which will fully harness the technologies and tools embedded within next-generation FSM solutions, let us now take a look at what tools are included in such systems and how they have evolved from the previous iteration of FSM software that is currently in place.

DATA INTEGRATION

Field service has always been a complex beast with many moving parts. However, modern field service in some respects is more complicated than ever due to the various systems of record (SOR) that may be in place. In previous iterations of FSM solutions, all too often, field service operations remained in a silo. Today, however, the benefit and value of widely available data flow across multiple business units are becoming increasingly acknowledged.

Therefore, there must be the potential to import and export data from one system to another within any modern FSM solution. Whether feeding into a CRM for sales, an ERP for resource planning, or even into a SOR that sits across production and R&D to drive forward product improvements, easy integration across non-service focused systems is critical.

GIS CAPABILITIES / INTEGRATION

Geographic Information Systems (GIS) has become an increasingly important part of many field service organizations workflows. However, while incredibly valuable, GIS data may come from multiple data sources, potentially stored in different SORs.

In the fast-moving world of field service, particularly if we are looking at reactive emergency response scenarios, then the ability to surface data from multiple sources both in the back office and, most notably for the engineer in the field, is crucial.

Although inclusion of GIS capability within next-gen FSM solutions like Geocall is relatively new, this practice is happening more frequently and will likely become the standard. While this may not be relevant for every industry vertical, within specific sectors such as Oil and Gas or Utilities, this could be a real game- changer that we will see emerge in the FSM 3.0.

SCHEDULING OPTIMIZATION

The old mantra of getting the right engineer, with the right skills, to the right job, at the right time will never fade as being the most central tenet of field service management and indeed service delivery as a whole. Across the last decade, we have seen tremendous strides made in scheduling with various approaches such as truly dynamic optimized scheduling and Darwinian algorithm-based scheduling. Such algorithm-based scheduling is paving the way for the increasingly widespread adoption of Robotic Process Automation (RPA) and AI leveraging the support of field service processes.

However, such sophisticated solutions are not always the right choice for each company or even for each type of service a single organization may have within its portfolio. The more sophisticated solutions are fantastic, for example, in dealing with large-scale service workflows, with large teams of field service engineers. They are also exceptionally effective in scenarios where there

may be complex requirements to place the right combination of skills across multiple engineers to meet the needs of the job.

In each of the above scenarios, we could see a different use case. In the first scenario, we could view an optimized scheduling engine as an opportunity to automate much of the dispatch workload, allowing the service organization to place human resources in roles that are more aligned to revenue generation than cost reduction. In such an instance, the human dispatcher adopts the role of supervisor. For example, ensuring the automation process is handling 80% of calls within standard parameters while taking control of the 20% that require a more nuanced approach (in line with the Pareto or 80:20 rule).

In the second scenario, where such a nuanced understanding of a more complex service scenario is required, we may consider assisted scheduling rather than automation.

The flexibility to have both solutions covered within a next-gen FSM solution is essential. However, what differentiates the new breed of FSM solution to many of the older legacy solutions is that scheduling tools, whether fully automated or assisted scheduling, should now always be expected to be dynamic. A dynamic solution can react to real-time data from the field, including engineer updates, traffic information, and customer data. This is a crucial aspect of next- gen solutions and allows for the work schedule to be constantly optimized.

EFFECTIVE REPORTING TOOLS

As we discussed earlier in the paper, the importance of data flowing between your FSM and other SOR has never been more critical. Service operations are now becoming a key driver in multiple core aspects of the broader business operations, and as such, the flow of information across the business must be seamless. Directly aligned to the importance of that data flow moving beyond the traditional silos is the ability for data to be surfaced in an easy yet meaningful way.

Within the context of next-gen FSM solutions, this primarily relates to dashboards that can be customizable for various levels of management allowing them to see the data in the manner they need. Modern-day reporting should give us the tools to simultaneously cut out the background noise of data unnecessary to the job at hand while tapping into the vast data lakes that are the bi-product of modern-day service management and bringing to the fore the data insight that is of use. It is also an expectation of next-gen FSM solutions such as Geocall to utilize different algorithms to translate the data into multiple use cases.

To illustrate this, let us look at an example most field service leaders would be familiar with, capacity planning.

We may have several data sets that we utilize in our capacity planning, say operations metrics that give us mean-time-per-job and technician utilization time. Alongside this, we may have customer job schedule data by volume and location. Then we may also have historical asset data that outlines the complexity of a given task.

In a next-gen FSM solution, we can apply different scheduling models, which allows us to compare and contrast based on various priorities and parameters. In essence, it is a glimpse into the future to see what could work and what may not.

In one scenario, we could run a model based on equity distribution to apportion workload fairly across all resources. Alternatively, we may want to run the same data against a logistic optimization to try to reduce travel and reduce time and reduce cost for the business.

In either scenario, we may want to factor in contingency capacity to accommodate any emergency work that comes in to ensure we have appropriate resources available to offer our customers total service support whenever called upon.

This scenario is just a brief example of the importance of effective reporting tools for service operations. The ability for a service leader to ask, “I want to make a change, what’s the impact?” and to effectively model out the answer to that question is a cornerstone of next-gen FSM.

MOBILE CAPABILITY

As we mentioned earlier in this paper, one of the significant shifts from FSM 1.0 to FSM2.0 was the inclusion of mobile. In the current status quo there is widespread provision of mobile solutions in the iterations of FSM solutions. However, next-gen solutions greatly magnify the complexity of such elements.

It is critical here to note that the complexity should always remain under the bonnet. Ultimately, the more sophisticated the technology on offer is, the more intuitive and seamless the experience should be for the end-user.

With this in mind, the mobile app of 2021 looks very different from those we would see just a few years ago, which were often little more than glorified push notifications showcasing job updates.

A modern FSM embedded mobile app should empower the engineer to capture accurate materials or asset data. It should guide them through structured workflows based on the job at hand while pulling in data from the asset itself.

It should play a pivotal role in ensuring that health and safety standards are met every time by placing clear checklists that technicians must complete before releasing additional information to the engineer. It should allow for a seamless customer interaction process- from having direct access for the engineer to order parts required when on-site, through the automated dispatch of invoices on receipt of an e-signature.

And returning to our concept of making the point of service as seamless as possible, the very best modern systems can do so in a truly dynamic fashion.

In Geocall, for example, the screen presents a truly dynamic experience for the field engineer or technician. The mobile solution understands the type of operation being undertaken and the most appropriate associated forms to capture the required data. Hotlinks are provided to the most relevant information within the knowledge library. The potential to record a solution to a currently unlisted problem allows the service organization to improve their knowledge base continuously.

The longer technicians use this tool, the more powerful it becomes.

And perhaps the most essential element of all, when it comes to identifying modern FSM technology, is that the mobile app links seamlessly to a virtual collaboration tool

VIRTUAL COLLABORATION / AUGMENTED REALITY

In the first section of this paper, we touched on how one of the primary shifts we will see as the dust settles and the new normal of field service begins to crystallize, is the more extensive use and many forms of remote service delivery will continue.This will take many forms. It may become a tool that technicians use for empowering self-service and self-maintenance for the customer. Workers may utilize it as the first level of support and enhanced triage tool. It may also support engineers in the field should they face an issue new to them requiring guidance from a more experienced colleague.

There are numerous papers dedicated to remote service tools available already on www.fieldservicenews.com, which are essential reading for all service companies seeking to embrace this modern approach to service delivery.

As a result, we won’t dwell on the topic too much here in terms of the benefits and considerations of adopting such a mechanism for service delivery. However, in the context of this paper, suffice to say, remote or virtual service collaboration tools are perhaps one of the most essential ingredients of FSM 3.0.

“Remote Service delivery and asset connectivity, however, are the agents of digital transformation. They do not just allow us to take the same processes and optimize them; they will enable us to rethink processes entirely and redefine service delivery...”

Embedding a remote service tool within an FSM system is currently the hallmark of next-gen systems. Some solutions have embedded remote service capability such as SPACE1 solution, whereas others will utilise 3rd party solutions and are reliant upon API based integration, increasing complexity and overhead.

Such a solution allows the service provider to have an experienced pair of eyes on-site almost instantaneously. It allows the service organization to access a site environment to either triage the information or resolve the problem remotely.

In more sophisticated tools such as SPACE1, we see the emergence of an intelligence-led knowledge management approach. Improved knowledge management means that a service organization can field the correct information at the right time to the engineer or the customer on-site via the tool. At the same time, the data automatically passes through image recognition technology, so it can automatically tag the correct information to make it more easily found at a later point if needed.

Such tools allow for rich information capture, whether images, videos or audio, while being utilized on-site, so every aspect of the maintenance or repair is catalogued correctly. Cataloging allows it to be fed back into the knowledge base to be used again in the future or even provide supporting documentation for invoicing or warranty disputes.

Additionally, we are seeing the rise in such tools in both training and on- boarding and critically reducing the time it takes to bring an engineer into the team before becoming a productive member of the workforce.

While all of the above tools are key factors in why service organizations should now upgrade or replace legacy systems, remote service tools are very much the poster boy of modern FSM solutions.

Again, the comparison to how Cloud and Mobile dramatically changed the game in FSM 2.0 holds true. Remote service, alongside IoT, are two technologies that will be the hallmark of FSM 3.0 as Cloud and Mobile where previously.

While there are therefore apparent comparisons, there is, however, a distinct difference.

The introduction of Cloud and Mobile, were perhaps the high watermarks of digitalization, allowing us to improve upon the efficiencies of traditional field service management processes.

Remote Service delivery and asset connectivity, however, are the agents of digital transformation. They do not just allow us to take the same processes and optimize them; they will enable us to rethink processes entirely and redefine service delivery in a more optimal way for the customer and the service provider.

This feature is just one short excerpt from a recent white paper we published in partnership with OverIT..

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content OverIT who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content OverIT who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Further Reading:

- Read more about Servitization & Advanced Services @ www.fieldservicenews.com/servitization-and-advanced-services

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Learn more about the impact of COVID-19 in the Field Service Industry @ www.fieldservicenews.com/covid-19

- Read more about OverIT on Field Service News @ www.fieldservicenews.com/exel

- Learn more about OverIT @ www.overit.it

- Follow OverIT on Twitter @ twitter.com/OverITSpA

Dec 07, 2021 • Features • White Paper • OverIT • Covid-19 • Servitization and Advanced Services

Field service has changed dramatically in the last 18 months, although we were already on a path of development from one phase of our evolution to the next as an industry.

In the first excerpt from a recent white paper we published in partnership...

Field service has changed dramatically in the last 18 months, although we were already on a path of development from one phase of our evolution to the next as an industry.

In the first excerpt from a recent white paper we published in partnership with OverIT, we start looking at what we should expect from an FSM solution suited to the post-pandemic world and how do we map an effective path from our existing legacy solutions.

This feature is just one short excerpt from a recent white paper we published in partnership with OverIT.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared withOverIT, sponsor of this premium content, who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

The pandemic alone didn’t distrupt how we approach service delivery, we had already planted the seeds some time ago. Undoubtedly, the pandemic accelerated our journey, but it pushed us faster down a path we were already on. It was the catalyst for change rather than the reason.

Servitization, for example, had already grown from a niche strategy to a mainstream concept discussed in service organization boardrooms around the world.

However, as we begin to see a clearer picture of the new normal, servitization is shifting from a nice to have to an essential strategic move for many companies.

Our post-pandemic world is one where we may begin to see a reversal of the drive to the globalization of the supply chain. Many manufacturers are still reeling from the disruption that was brought to their business by external factors. One solution is a more decentralized approach that, while proving more costly, would be far more robust should we face similar challenges once again.

Another external factor driving servitization is the focus on the circular economy becoming more pressing as we address climate change issues impacting us all. A focus on sustainability suddenly moves beyond nice- sounding PR. It is now an essential facet of how we, as an industry, must embrace bold thinking as we consider field service in such a context.

Servitization, for many companies, allows for shifting the responsibility of output to the service provider, leading by necessity to more intelligent design of assets that are designed to last longer and can be more easily maintained.

Similarly, with remote service delivery, we see external factors come into play that could shape its role in the future of service delivery. Remaining on the point of sustainability, for example, the ability to reduce the carbon footprint of the field workforce is hugely boosted by the adoption of remote service tools and technologies.

Yet, only a few years ago, remote service delivery was very much the domain of best-in-class leading-edge adopters. Today it is being embraced across our industry. Remote service delivery, an approach to maintenance that companies adopted mainly out of necessity during the times of lockdown, has shown us en masse that there could be another way of approaching service delivery, problem triage, and issue resolution.

These are two very brief examples of how the industry is currently going through a significant process of evolution, driven in part by factors outside of our control. However, ours is an industry that adapts well. Ours is an industry populated with problem solvers and forward thinkers, a natural result of the often linear progression from field engineer to management that many of our industry’s leaders have chosen to take.

Indeed, it was not that long ago that we went through a similarly significant shift, as service moved from cost-centre to profit centre for a majority of service organizations. Again, this shift was, at first, glance a reaction to external disruption. Many point back to the 2008 recession as a pivotal moment in that shift.

With the global economy fractured and product margins being pushed to paper-thin levels, we witnessed a focus on service both as a critical differentiator to win and retain business but also as a vital revenue generator.

This came at a time when CAPEX investment for new assets was scarce and a desire to sweat assets that much longer, was wholly reliant on strong service agreements. Yet, while the 2008 recession certainly played its part in shaping that phase of industry evolution, much like the ongoing uncertainties in both economic and other factors are doing today, that first decade of the new century showed individuals at the forefront of innovative service design focuisng on service as a profit center.

Equally, like today, that shift in thinking was inspired by and empowered by a wave of technological innovation. As much as Augmented Reality, the Internet of Things, and Artificial Intelligence are changing the way we approach service delivery moving forward now, both Cloud and Mobile Computing radically altered the idea of what was possible then.

If we think back to the systems that preceded that era, there was a basic foundational layer within those early FSM solutions that were built and expanded upon, thus creating a new generation of solutions.

Elements such as scheduling and engineer-orientated mobile applications were often best-of-breed solutions designed for one purpose that integrated into the FSM platform. Then as we began to see these elements become standard inclusions, we moved into an era of FSM2.0.

Similarly, we have now begun to see new technologies like remote assistance tools, AI-based triage, and next-generation dynamic scheduling move through maturation. These tools that were often external to the FSM solution are becoming embedded in sophisticated next-generation platforms such as Geocall from OverIT as we begin to see the emergence of FSM 3.0.

In this paper, we shall explore what we should expect from such solutions and outline some guidance on the migration from an existing legacy solution to a solution designed with the emerging challenges of the new normal in mind.

This feature is just one short excerpt from a recent white paper we published in partnership with OverIT..

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content OverIT who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content OverIT who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Further Reading:

- Read more about Servitization & Advanced Services @ www.fieldservicenews.com/servitization-and-advanced-services

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Learn more about the impact of COVID-19 in the Field Service Industry @ www.fieldservicenews.com/covid-19

- Read more about OverIT on Field Service News @ www.fieldservicenews.com/exel

- Learn more about OverIT @ www.overit.it

- Follow OverIT on Twitter @ twitter.com/OverITSpA

Dec 03, 2021 • Features • Mize • Parts Pricing and Logistics • GLOBAL • customer experience

Durable goods manufacturers have long played a part in the circular business economy, placing particular emphasis on improving productivity and streamlining reverse logistic supply chain processes to achieve time- and cost-saving benefits.

Durable goods manufacturers have long played a part in the circular business economy, placing particular emphasis on improving productivity and streamlining reverse logistic supply chain processes to achieve time- and cost-saving benefits.

While a laser focus on operational efficiency is important in reverse logistics, it doesn't always optimize the most important component in the equation: the customer experience. The old adage that the customer is always right is especially true when something goes wrong, a critical repair is needed to keep your customer's business moving forward, or a customer needs to know when they can expect to receive what you've promised.

Optimizing reverse logistics for customer experience can make the difference between a customer that experiences momentary frustration and one who seeks out a competitor.

Fortunately, durable goods manufacturers are capturing the opportunity to improve the customer experience at every touchpoint, including key points in the reverse logistics supply chain (RLSC). According to a whitepaper by The Blumberg Advisory Group and Mize, durable goods manufacturers have "moved beyond looking internally within their organizations to find ways to cut costs and streamline operations. They are now looking externally at how customer-facing activities may impact the ability to scale and grow their reverse logistics supply chain operations."

THE COMPLEXITY OF THE RLSC IN DURABLE GOODS MANUFACTURING

There's no shortage of complexity in the reverse logistics supply chain and the challenges can be daunting—and resource intensive. In 2020, Statista reported more than $636 billion in reverse logistics spending. They predict that number will exceed $958 billion before the end of the decade.

That complexity is inherent in durable goods manufacturing and compounded by the legacy ERP and supply chain management (SCM) solutions that lack the capabilities to overcome these challenges. Legacy systems often comprise disparate applications, which lack the business logic and process flow required to provide critical feature-functionality, robust reporting, and analytic capabilities.

For instance, a lack of integration can make it challenging for original equipment manufacturers, channel partners, and service providers to forecast necessary resources, like labor and parts, and scale-up in time when needed. It can also prevent seamless data gathering and transfer, causing channel partners to face inaccurate/delayed reporting and gaps between returns shipment and credit issuance. And for the customer, a disjointed RLSC almost always creates a frustrating return process due to issues like fragmented customer service, lack of repair status updates, and extended wait times.

THE COMPLEXITY OF THE RLSC IN DURABLE GOODS MANUFACTURING

The right depot repair solution will help to reduce operational costs, optimize service experience, and build stronger customer relationships. Depot repair is a critical component of RLSC that focuses on streamlining and automating the end-to-end repair process, from initiating a customer service request to delivering the repaired product back to the customer.

Mize Depot Repair Management is designed to fix inefficient processes at centralized repair depots, shortening product downtime, raising technician productivity, and lowering parts inventory costs on repair orders. In addition, its cloud-based digital platform improves visibility for all stakeholders, making it easy to communicate with customers and build stronger customer relationships.

DEPOT REPAIR IMPROVES VISIBILITY AND TRANSPARENCY FOR A BETTER CX

Customer expectations and supply chain obstacles evolve consistently, which means your approach needs to evolve as well. Mize offers a Service Lifecycle Management solution, including Depot Repair Management, that connects manufacturers to their end customers and everyone in between, reducing operational costs and maximizing the lifetime value of customer relationships.

Download Mize latest whitepaper to learn more about how leading organizations are optimizing the reverse logistics supply chain and better meet customer needs.

Further Reading:

- Read more about Parts, Pricing & Logistics @ www.fieldservicenews.com/parts-pricing-and-logistics

- Learn more about Mize on Field Service News @ www.fieldservicenews.com/blog/all-about-mize

- Read more articles and news about Mize on Field Service news @ www.fieldservicenews.com/mize

- Find out more about Mize @ www.m-ize.com

- Read more on Mize's blog @ www.m-ize.com/blog

- Follow Mize on Twitter @ twitter.com/mizecom

Dec 01, 2021 • Features • Digital Transformation • IFS • Sarah Nicastro • SimPRO • durabook • Servitization and Advanced Services • Iwi Lin • Ricky Sevta

Kris Oldland, Editor-in-Chief, Field Service News reflects on the alignment of digital transformation and servitization - the two key trends driving innovation and evolution in our industry...

Kris Oldland, Editor-in-Chief, Field Service News reflects on the alignment of digital transformation and servitization - the two key trends driving innovation and evolution in our industry...

There have been two key trends that have been consistently present within our industry for a number of years. Both have been at the heart of discussions in boardrooms and on conference stages alike. Implementation of both has been accelerated by the pandemic. These two trends are of course Digital Transformation and Servitization - but just how closely related are they?

For Sarah Nicastro, Vice President of Customer Advocacy, IFS the two are very closely aligned.

"We believe that Servitization and Digital Transformation are inextricably linked, in that the progression of digital is a major factor in the increased demands customers have that are prompting companies to Servitize as well as in the fact that it’s impossible to Servitize without digital capabilities," Nicastro explains.

"To seize the potential of advanced services, companies must view Digital Transformation as key to success. Digital is required to gain insights into the performance of assets in a way that allows a proactive and predictive response, to optimize the utilization of both its workforce and inventory in the manner necessary for guaranteeing outcomes, and to ensure the customer experience is seamless and informed.

"Data is also proving to be an integral part of an advanced services value proposition in the form of providing customers unique insights gleaned from digital tools in use. As such, companies should seek a modern digital platform that provides a range of capabilities to eliminate the failure points common in a disjointed environment and to protect the integrity of the customer experience. " she adds.

This is a comment that is echoed by Iwi Lin, Marketing Manager, Durabook.

"Digital transformation is already happening within the business-to-business sector, meaning organizations across every industry need to embrace this digital change," he comments.

"Servitization can only be a consistent and reliable revenue source if your business performance remains equally efficient and dependable..."

- Iwi Lin, Durabook.

"The adoption of emerging technology is where true industry revolution occurs, determining who will rise to the top and who will fail over time. Companies that implement technology to streamline processes, optimize budgets and improve overall workforce performance are predicted to outlast their competition.

"However, servitization can only be a consistent and reliable revenue source if your business performance remains equally efficient and dependable, which is where rugged devices come into play. These computers are fast becoming the focal point of these technologies as they enable organizations to realize even greater operational capabilities,"

Indeed, our world both inside and beyond field service is evolving rapidly in terms of technology and as we add the further pressures of a servitized business model into what is an already complex mix of many moving parts that constitute field service then the importance of being able to leverage, but also importantly trust the technologies we deploy throughout digital transformation is critical.

As Lin adds "With technological evolutions in IoT, 5G, Augmented Reality (AR), machine learning and AI, companies investing in new technologies will be able to predict and prevent operational failure. Computer manufacturers that provide rugged devices can help organizations understand how to operate these devices in the field to enable their digital transformation programs and ensure new technologies are used for their maximum benefit.

"With uninterrupted servitization a crucial factor for business success, the latest equipment is designed with optimum efficiency in mind. Rugged devices are the only models that can withstand the frequently harsh conditions many field computers must endure.

"The latest devices also contain sensors that feed operational data back to the manufacturer on the product’s condition, reducing maintenance issues and downtime. Should a problem arise, the manufacturer or service provider will be automatically notified by the faulty part so it can be quickly fixed. While they may require a greater initial outlay, they are far more cost-effective in the long term because of this lower need for maintenance costs."

"Servitization at its core means providing outcomes rather than products or even services – it’s a company-wide transformation in the identity of the business and the customer value proposition."

- Sarah Nicastro, IFS

Coming from an industry where reliability in the field is a critical component of the success of their products, Lin's point raises an important distinction between servitization and digital transformation. While they are invariably two facets of the same conversation, the latter is the enabler, while the former represents the true paradigm shift.

As Nicastro explains, "Servitization at its core means providing outcomes rather than products or even services – it’s a company-wide transformation in the identity of the business and the customer value proposition, not a simple addition to the service portfolio.

"However, in many cases this transition occurs over time in a phased manner to ease the impact on culture and operations and to help manage change."

Of course, while technological innovation or advances in service design thinking are important, these all become something of a moot point if they are not aligned with what our customers actually need and want. This is a critical part of the discussion which cannot be overlooked.

"Without customers, nothing happens," states Ricky Sevta, CRO, simPRO bluntly.

"Customers we’ve talked with agree. They also know it’s a tricky balance, tailoring your services to the unique needs of your customer while also providing high-quality service to every customer. You also have to do it better and faster than your competitors, and still turn a profit.

"In our experience working with all types of trades businesses, we believe technology like job management software, can help you do it all.

"Job management software helps you better manage all the moving parts in your business, and gives you insights (data) into how well you're truly performing in each area of your business. More importantly, it shows the relationship between these areas.

"You can then pinpoint how your performance, in these areas, good or bad, ultimately impacts the customer experience," Sevta adds.

"Your customers make everything happen. Why make them wait?'

- Ricky Sevta, simPRO

"For example, how does proper stock management impact customer service? Say your field staff arrive at a job only to realize that they don’t have what they need. Now they’re wasting the customer’s time and their time. This can lead to an irritated customer and a job that takes much longer than it needs to.

"Your engineers are set up for success, and empowered to provide good customer service when they know that they have the right materials for every job, and can check stock from anywhere at any time, but so is the rest of the team. With field management software, your admin team can check inventory while talking to a customer rather than having to take their number down, manually check the stock and then call them back."

"Your customers make everything happen. Why make them wait? Job management software, especially cloud-based software, gives staff all of the relevant information they need to deliver the best customer service no matter whether they're remote or on-site," Sevta concludes.

Indeed, there is a broad mix of tools available for field service companies of all shapes and sizes, across all sectors in today's market. Digital transformation is all around us and will continue to evolve at pace. As to will the servitization movement, with service portfolios becoming more advanced and sophisticated as we embrace such tools.

However, as Sevta rightly states, keeping the customer centre to all we do is the one true key to success.

Further Reading:

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Read more about Servitization and Advanced Services @ www.fieldservicenews.com/blog/tag/servitization-and-advanced-services

- Read more about IFS @ www.ifs.com/

- Read more about Durabook @ www.durabook.com/

- Read more about simPRO @ www.simprogroup.com

Dec 01, 2021 • Features • connectivity • Digital Transformation • GLOBAL • TELENOR CONNEXION • LTE-M • NB-IOT

In this final feature of a series of excerpts from a recent white paper published by Telenor Connexion, we look in detail at the difference between LTE-M and NB-IOT, as a guide to make the optimal choice for your business.

In this final feature of a series of excerpts from a recent white paper published by Telenor Connexion, we look in detail at the difference between LTE-M and NB-IOT, as a guide to make the optimal choice for your business.

This feature is just one short excerpt from a white paper published by Telenor Connexion.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Telenor Connexion who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Adaptability to New Use Cases

When choosing a connectivity technology, the complete lifecycle of the connected product must be taken into consideration. Enterprises need to choose a technology that can grow with new use cases.

Imagine a product called “The connected door”. Initially it should just be possible to open and close the door and the door should send usage statistics every night to the cloud. The typical door has a lifecycle of 10 years. After just looking at the initial use case, the data amount is very low, so the focus is on technology with the lowest bandwidth and the door is mass produced and successfully launched. After three years the enterprise wants to monitise this success and add new value - the door should not just connect, but also interact with a parcel delivery service. For use cases where the application can be expected to evolve over time it is thus important that the whole solution has potential to develop. LTE-M provides greater potential to grow over time.

Due to its wider bandwidth LTE-M provides more adaptability to new use cases where the use cases of the IoT solution will develop over time. NB-IoT is an alternative when the requirements are more static and known from start.

Due to the shutdown of 2G and 3G networks in many parts of the world many legacy use cases need to be transferred to new connectivity technology.

We believe that 2G technologies will continue to be available in many parts of the world and outlive 3G. In Europe we anticipate 2G will be available until 2025, due to the legally required emergency services in the EU which depend on 2G technology.

As the coverage of LTE-M and NB-IoT deployments may not, as of today, be good enough everywhere, we recommend enterprises verify coverage in more detail and/or ensure devices are compatible with existing technologies as a backup.

IoT use cases will eventually move from old to new technology. As LTE-M meets or exceeds the technical characteristics of 2G/3G services, it appears to be a natural, evolutionary step. NB- IoT has lower responsiveness and limitations in mobility and may be relevant for use cases with lower requirements.

Global Availability

We believe that LTE-M will be the first to become a globally available technology as it has technically been designed for roaming from the start, like all other 2G, 3G, 4G and 5G technologies. NB-IoT was initially designed for static devices only, and roaming has been added later as afterthought.

Operators will be more reluctant to support incoming roaming NB-IoT devices that use network resources, but hardly generate revenue. Roaming on NB-IoT will most likely be limited to the business units within an operator group. We expect that LTE-M roaming will be available globally in the coming years, similarly to normal 4G roaming, and it is indeed already available today as a best effort offering on existing 4G roaming contracts.

LTE-M has been designed for roaming from the start and can leverage existing roaming and wholesale business models between operators. NB-IoT will require new business models to be a good alternative for global connectivity. Therefore we expect that LTE-M will be relevant for international IoT solutions earlier than NB- IoT.

Software Updates and Security

IoT devices can have a typical life span of 10 to 15 years. For many use cases it is desirable to update the software in the device several times over its lifecycle. Therefore, enterprises must choose a technology that can handle updates to work with modern software development practices - and to keep devices secure.

Enterprises typically use agile software development (small and frequent increments) to decrease time to market. This makes the waterfall approach to software development – where large software are deployed that are never touched again - a practice of the past.

The characteristics of NB-IoT mean it is not suitable for upgrading large fleets of IoT devices. This is expected to be addressed in a future version of NB- IoT, called NB2. In this variety software upgrades can be managed using multi-cast.

This means that there will be two varieties of NB-IoT available - NB1 and NB2 (also sometimes called LTE-cat NB1 and LTE Cat NB2). The current status is however that today most networks only support NB1, and it may take years before NB2 is widely available.

Increased security improvements and the agile software development methods used today, will continue to drive software updates. This has a large impact on the bandwidth consumption during the lifecycle of devices which is often underestimated. LTE-M is considerably better at handling device updates as its higher bandwidth can handle more data.

Moving Devices

Previous mobile technologies all support devices that can move around without connectivity being interrupted. Devices constantly measure radio signals of nearby radio towers (cells) in the network and dynamically and seamlessly adjust their signaling to different towers (cells). Here we see significant differences between NB-IoT and LTE-M.

NB-IoT is designed for static devices. It is designed to increase battery life by reducing measurement of signals to nearby radio towers (cells). When NB-IoT devices are moved, sessions may get dropped, or devices may need to reconnect. This can lead to interruptions and reduces battery life. This makes NB-IoT less suitable for moving devices.

LTE-M on the other hand is designed for moving devices, just like 2G, 3G, 4G and 5G. LTE-M can support moving devices without losing data sessions, at speeds of up to 200km/hr.

LTE-M is the better choice for moving devices as it has been designed for this from the start. As NB-IoT is designed for static devices it can lead to interruptions if devices are moved.

Remote Control Devices

If devices need to be remotely controlled, responsiveness is important.

Devices controlled by people need a fast and consistent response. LTE-M provides the same consistent response time as regular 4G, so it can be used by people to remotely control devices. NB- IoT is designed to send small amounts of data and is not designed for a fast response. With NB-IoT it may sometimes take up to 10 seconds to receive a response from a device.

Not all use cases need a fast response and it may for example be perfectly acceptable to wait 10 seconds for sensor readings.

When there is human interaction a slow response risk being perceived as poor usability, which could harm the brand perception of enterprises.

LTE-M is needed for a fast and consistent response, while NB-IoT can handle use cases where a delay of minutes is acceptable.

Voice Readiness

LTE-M is designed for voice and the specification includes Voice over LTE (VoLTE) - which is deployed by 194 operators in 91 countries.

Today however, VoLTE is not globally available in LTE-M networks and there are not many hardware modules that can support VoLTE over LTE-M. We expect that VoLTE will grow in importance in the coming years in LTE-M, just as it did in the consumer market for LTE.

The bandwidth and especially the responsiveness of LTE-M can also be used as an alternative to Voice over IP solutions. Devices need to respond quickly to calls and must be able to send and receive data at the same time (full duplex). Only LTE-M can support full duplex communication.

NB2 adds push to talk technology to NB-IoT, only one party can talk at any one time because the technology is half duplex, like walkie-talkies used to be.

LTE-M is designed for voice with Voice over LTE and can also be used for Voice over IP with full duplex. NB2 adds push to talk technology to NB-IoT but only at half duplex.

SIM Localisation - EUICC

Physically swapping the SIM card of deployed devices can be a costly and complicated process, especially in an IoT environment. SIM cards with eUICC technology allows switching of identity over the air, without the need for physical replacement of SIM cards.

When the life cycle of connected devices is longer than the commercial agreement with an operator, the eUICC technology makes a change of operator possible. eUICC can also be used for devices deployed in locations where roaming is not possible. While eUICC is still in an early stage today it will become a vital technology for large and international deployments of IoT devices.

Not all operators support the combination of NB-IoT and SMS which means that eUICC cannot be initiated in many networks. The bandwidth of LTE-M is also more suitable for transmission of SIM profiles, just like software updates. Enterprises considering eUICC should therefore also consider LTE-M.

Time to Market - Internet Competence

Time to market is essential when launching new products. Connectivity technology is only one aspect of the product. Access to people with the right competence is vital to ensure time to market which is why many enterprises choose common technologies over specialized technologies. Common technologies make product development faster, and product maintenance more cost efficient, because it is easier to get access to developers and other specialists.

The internet is built on technologies like IP, TCP, UDP and TLS. These protocols are familiar and easy to use for developers, as they hide much network complexity and are easy to scale without central control.

NB-IoT is designed to perform in local deployments, for example connecting streetlights in a city. Here it is not necessary to use standard internet technologies, such as IP.

Enterprises can access their devices through the Service Capability Exposure Function (SCEF) provided by the network operator. SCEF simplifies the access to devices by hiding the complexity of the operator’s network making device access familiar to application developers.

Today SCEF is available in some networks for local deployments. Enterprises that would like to use NB- IoT without IP would need to connect to all individual NB-IoT operators that support SCEF.

The roaming and interworking of SCEF is standardized, but it will take several years before SCEF are widely deployed and roaming is available.

LTE-M is using standard IP protocols which makes it straightforward to develop applications. NB-IoT is using tailormade protocols requiring specific application development and competence.

CONCLUSION AND RECOMMENDATIONS

Deciding between the new mobile connectivity technologies, LTE-M and NB-IoT, requires an understanding of the key differences between them.

LTE-M and NB-IoT are both globally available, vendor independent technologies, based on open standards. With the introduction of eUICC enterprises can take a commercial decision based on the most suitable technology and irrespective of operator.

Both LTE-M and NB-IoT enable relevant use cases and are telecom grade, which means they operate on dedicated radio frequencies in telecom networks with a proven capability to scale, and with committed support through the whole life cycle from the operator.

Both technologies also support improved battery life and substantial coverage enhancements, when compared to older mobile technologies.

For Most International Use Cases LTE-M is the Preferred Alternative

- LTE-M is the better alternative with respect to handling firmware and software updates that are expected during the lifecycle of the devices. LTE-M is built for roaming and has the best support for international deployments using a single point of contact and subscription for enterprises.

- Both LTE-M and NB-IoT have significantly improved indoor coverage compared with LTE.

- LTE-M is a better alternative for moving devices as it will not lose ongoing data transfers.

- LTE-M is prepared for voice technology and Voice over LTE.

- With LTE-M, devices can react in milliseconds if required, enabling use cases where a fast response is needed which is relevant for the usability of human-machine interactions.

Recommendations

Choosing the right connectivity technology is one of the critical decisions when implementing an IoT solution. The right choice is essential for deploying a well working solution in a cost efficient way and that can develop over time. New mobile IoT connectivity standards, LTE-M and NB-IoT, opens up for new and evolved use case by offering better coverage, longer lasting batteries and/or lower device cost. In addition they offer a future-proof path as 2G and 3G networks are gradually sunset across the world.

For most international IoT solutions LTE-M will be the preferred connectivity standard as it is expected to become globally available faster and to be more straightforward when developing and maintaining applications. NB-IoT may still be the better choice for some applications, -for example for very large scale sensor networks where the requirements are known at deployment and the best possible indoor coverage is absolutely essential.

As of today neither LTE-M nor NB-IoT are deployed widely enough to be solely relied on for international fleets of devices. For now it is recommended to use hardware that is able to use LTE-M or NB-IoT as well as networks with mature footprints, for example,

2G and/or 4G. The deployment status of mobile IoT network is developing rapidly and therefore the right setup will vary over time.

Independent on the choice of technology standard, Telenor Connexion can help you with all your connectivity needs. Get in touch to find out more about the first steps to take for your low-power, wide-area IoT application.

This feature is just one short excerpt from a white paper published by Telenor Connexion.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Telenor Connexion who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Telenor Connexion who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Further Reading:

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Read more about Mobile Connectivity @ www.fieldservicenews.com/connectivity

- Read more about Telenor on Field Service News @ www.fieldservicenews.com/telenor

- Learn more about Telenor Connexion @ www.telenorconnexion.com

- Follow Telenor Connexion on Twitter @ twitter.com/t_connexion

- Connect with Telenor Connexion on LinkedIn @ www.linkedin.com/telenor-connexion-ab/

Nov 26, 2021 • Features • White Paper • FieldAware • Leadership and Strategy • customer experience • customer success

In this final feature from a recent white paper we published in partnership with FieldAware, we discuss if customer satisfaction metrics are suitable to identify a measure of success in a servitized or customer success-based service model.

In this final feature from a recent white paper we published in partnership with FieldAware, we discuss if customer satisfaction metrics are suitable to identify a measure of success in a servitized or customer success-based service model.

This feature is just one short excerpt from a recent white paper we published in partnership with FieldAware.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content FieldAware who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Do we need to rethink how we measure success within our organization if we move towards a servitized or customer success focused model? This is something of a complex question, and in many ways, the answer is both yes and no.

From an operational perspective, as we put forward earlier in this paper, broadly what defines operational success in a transactional break-fix service offering largely remains the same definition of success that we would see in a servitized model.

To reiterate, in the traditional break-fix setup, metrics like mean-time-to-repair, first-time-fix-rate, and technician utilization are all indicators of how efficiently the service organization can meet the customer’s external demands and expectations.

In a servitized offering, those same metrics remain vital for ensuring that the field service operation is running at a level of efficiency that makes it both feasible and financially rewarding for the service provider to offer such as solution.

Yet as the Field Service News Research study from late 2019, Understanding the metrics that matter in a rapidly changing field service sector, revealed, of those organizations that had introduced some level of servitization into their service portfolio, over 80% of them had made changes to the KPIs they measure.

Also, remember the statistic we referenced earlier in this paper from that same report- over half (51%) of all field service organizations now placed equal importance on CSAT metrics as they did operational metrics – a statistic that has steadily risen year on year since Field Service News Research began hosting benchmarking studies in this area back in 2013.

Yet, when we think of customer satisfaction metrics, are these suitable to identify a measure of success in a servitized or customer success-based service design model?

Rudimentary statistics such as Net Promoter Score can offer a broad overview of service standards. More detailed tools like customer surveys allow more specific insights to come to the fore, and modern tools such as sentiment analysis can fill in the gaps between the two.

However, all CSAT metrics are the equivalent of driving while looking in the rearview mirror and while valuable indicators, are perhaps not focused enough for the end-goal of defining customer success.

“CSAT metrics are the equivalentof driving while looking in the rearview mirror and while valuable indicators are perhaps not focused enough for the end-goal of defining customer success...”

In earlier sections of this paper, we have touched on how co-creation often lies at the heart of many successful servitization case studies and the potential importance of an onboarding team.

When it comes to defining the core metrics for a customer success-based service model, a critical role of the onboarding team (and also of pre-sales and/or account management) should be to work with the customer to identify a shared set of metrics that will shape how success is defined.

This may require data sets from both organizations to combine a new set of KPIs that allow the service provider to ensure they meet the requirements. Should these KPIs indicate an issue, then traditional operational KPIs can provide an insight as to why. Meanwhile, broader CSAT metrics can offer an indication of the overall temperature of the service organisations success.

This more complex understanding not only of what success looks like for each customer but also leveraging existing KPIs to ensure that is happening at the macro and granular level, serves once more to re-enforce the importance of not only having the tools to empower effective service delivery but also the critical importance of reporting tools that allow the service provider to quickly and easily keep their finger on the pulse of how the service operation is performing.

In addition, such reporting tools allow the service provider to offer a layer of transparency that is crucial in communicating with the customer. This transparency leads to a relationship founded on trust. In summary, new metrics will evolve, but the old metrics remain vital and access to data is key in all areas.

This feature is just one short excerpt from a recent white paper we published in partnership with FieldAware..

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content FieldAware who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content FieldAware who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Further Reading:

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Read more about Data Management @ www.fieldservicenews.com/data-management

- Read more about FieldAware on Field Service News @ www.fieldservicenews.com/exel

- Learn more about FieldAware @ www.fieldaware.com

- Follow FieldAware on Twitter @ twitter.com/fieldaware

Nov 25, 2021 • Features • Digital Transformation • Aquant • Covid-19 • customer experience

Aquant, has recently published the 2022 Service Intelligence Benchmark Report, now available at Field Service News, which offers an in-depth analysis of field service performance and customer satisfaction in a year of talent shortage, COVID service...

Aquant, has recently published the 2022 Service Intelligence Benchmark Report, now available at Field Service News, which offers an in-depth analysis of field service performance and customer satisfaction in a year of talent shortage, COVID service pivots, and shifting customer demands. In this final excerpt from the report, we discuss how companies can look beyond KPIs.

This feature is just one short excerpt from a report published by Aquant

www.fieldservicenews.com subscribers can read the full report now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Aquant who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Aquant who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

The Customer Experience Gap

The Customer Experience Gap shows the difference between what customers expect and what your organization delivers.

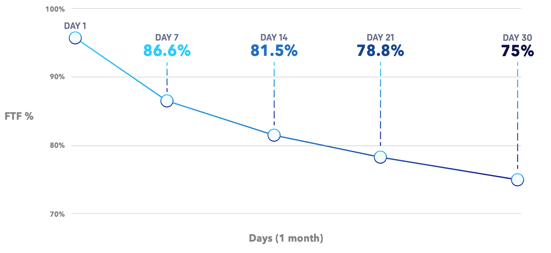

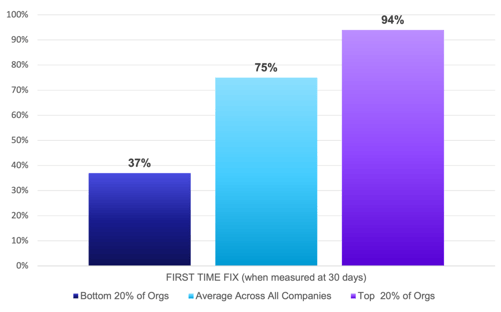

Our analysis shows that companies who measure FTF rates in 7-day or 14-day windows are setting the stage for a wide experience gap—which leads to frustrating customer experiences. The moral of the story: a few metrics can’t provide the entire picture. It’s time to look at experience as a whole.

Instead of defining FTF in arbitrary time increments (7 days, 14 days, or 21 days), think about it in terms of the natural service cycle. Our research shows that measuring in 30-day windows strips out false-positive FTF rates.

Understand where your organization falls on the Customer Experience Gap chart.

- If your FTF rate is similar when measured at 7 days and 30 days, you have a small gap.

- If your FTF rate has a wide variation (usually a high rate at 7 days and a low rate at 30 days), you have a large gap.

- If you have a large gap, your team is focused on hitting their numbers instead of focusing on great customer experiences.

Why FTF Rates Vary by Time

When measured in short windows (like 7-day increments), jobs where a technician made an incorrect fix—but got the machine to work temporarily—will be marked as complete. But an incorrect fix is only a temporary measure, and the machine will continue to break down until properly repaired. For instance, a customer may call for service two or three times in a 30-day window. If you only measure in 7-day increments, your dashboard may show you successfully completed three jobs for one customer. In reality, these were three failed visits. This environment also leads to customer escalations and customer complaints that management may deem as “surprise complaints” that they didn’t see coming.

When it comes to service, it’s just as important to maximize the time between events and failures as it is to fix things correctly the first time. The less a customer needs a technician on-site, the better. This means the customer’s needs are being met.

Two Examples of Poor Customer Experiences

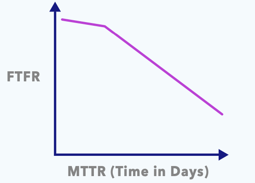

Company A: KPIs are not aligned to customer outcomes

When FTF curves start out flat, it means that the company likely incentivizes high FTF rates over deep problem-solving. That’s shown by the curve getting steeper at the end of a 30-day cycle, indicating that the FTF rate is plummeting.

The key takeaway: Company A is not closely monitoring FTF rate—or there is no incentive to maintain a high rate over a long period of time—leading to poor customer experiences.

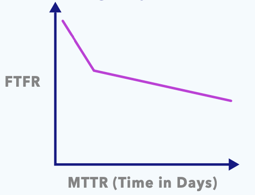

Company B: KPIs are not aligned to customer outcomes

Here, the FTF rate starts out high and eventually flattens out. This may indicate that more preparation, information, or triage was needed before visiting a job site. A return visit would most likely be required to successfully solve the problem. Unlike Company A, Company B eventually solves root problems, but it requires several visits.

The key takeaway: Company B is trying to provide great customer service, but has some limitations that hinder quick and accurate outcomes, such as a lack of prep or an employee knowledge gap.

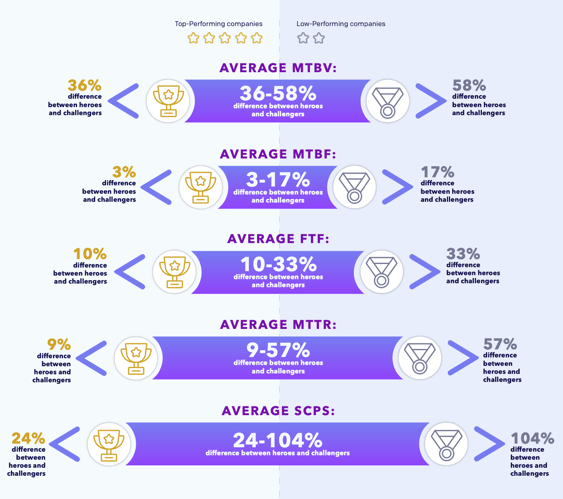

The Skills Gap - A Profile of the Top and Lowest Performing Organisations

What does the knowledge gap have to do with hitting KPIs?

If there is a large knowledge gap between team members, performance will vary—and so will customers’ experiences. That’s why it’s crucial to make sure that your technicians are equally knowledgeable about the equipment that they service and up-to-date on specific customer preferences.

Determine your team’s skills gap.

To increase your team’s knowledge and success, you must first identify how much of a gap exists between your star technicians (heroes) and underperformers (challengers).

For this report, we calculated the percentage difference between heroes and challengers across all organizations on the following page. We divided it into:

- Above average organizations

- Above performing organizations

- Below average organizations

A Snapshot of high performing and low performing organizations

The top 20% of organizations have a smaller workforce skills gap. A workforce with a more equal knowledge distribution results in more consistent customer experiences.

Why the Skills Gap Matters

A bigger distance between heroes and challengers leads to:

- Decrease in customer satisfaction

- Increased workload on your already overburned experts

- Increase in service costs

- Less capacity for organizational resilience

- Negative impact on growth

What's Next?

The service industry is facing unprecedented workforce shortages and increasing customer demands. A better way to overcome these challenges is to understand your business on a much deeper level than you do today so you can tailor service for every customer. Here’s where to start.

This feature is just one short excerpt from a report published by Aquant.

www.fieldservicenews.com subscribers can read the full report now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Aquant who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Aquant who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

Further Reading:

- Read more about Aquant on Field Service News @ www.fieldservicenews.com/aquant

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Read more about Leadership & Strategy @ www.fieldservicenews.com//leadership-and-strategy

- Learn more about Aquant @ www.aquant.io

- Follow Aquant on Twitter @ twitter.com/Aquant_io

Nov 24, 2021 • Features • connectivity • Digital Transformation • GLOBAL • TELENOR CONNEXION • LTE-M • NB-IOT

In this second feature of a series of excerpts from a recent white paper published by Telenor Connexion, we look in-depth at the characteristics of LTE-M and NB-IoT technologies and how they will affect the market.

In this second feature of a series of excerpts from a recent white paper published by Telenor Connexion, we look in-depth at the characteristics of LTE-M and NB-IoT technologies and how they will affect the market.

This feature is just one short excerpt from a white paper published by Telenor Connexion.

www.fieldservicenews.com subscribers can read the full white paper now by hitting the button below.

If you are yet to subscribe you can do so for free by hitting the button and registering for our complimentary subscription tier FSN Standard on a dedicated page that provides you instant access to this white paper PLUS you will also be able to access our monthly selection of premium resources as soo as you are registered.

Data usage note: By accessing this content you consent to the contact details submitted when you registered as a subscriber to fieldservicenews.com to be shared with the listed sponsor of this premium content Telenor Connexion who may contact you for legitimate business reasons to discuss the content of this white paper, as per the terms and conditions of your subscription agreement which you opted into in line with GDPR regulations and is an ongoing condition of subscription.

LTE-M AND NB-IOT TECHNOLOGIES - INCREASED BATTERY LIFE, ENHANCED COVERAGE AND SIMPLIFIED HARDWARE

LTE-M and NB-IoT are designed to support IoT devices that need a long battery life or are used at locations that are difficult to reach with normal 4G technology, such as deep indoor locations.

So how are they different and how will they affect the market?

Battery Life and Increased Coverage

Battery life is increased by reducing the radio communications between device and network, and devices can go into sleep mode or listen less often to the network. LTE-M and NB-IoT both offer better coverage than 4G in, for example, deep indoor or remote areas.

There is however a trade-off between battery life, coverage and responsiveness. To leverage this requires access to new types of functionality in the network- for example PSM and EDRX use cases that need a fast response are less suitable for battery saving and enhanced coverage.

Likewise, devices that need a life cycle of 10 years need to be deployed in areas with good coverage. To support a balanced approach, battery saving and enhanced coverage are applied in step with each other. Significant improvement in battery life and coverage can be achieved by sleep mode and applying the right level of repetitions.

New Pricing Models Likely to Emerge

Pricing models for LTE-M and NB-IoT will likely be different to traditional telecom pricing because of the different traffic profile involved with IoT connectivity. There will be a vast number of connected LTE-M and NB-IoT devices but they will send low amounts of data. Rather than the data consumption per device price model, network providers will most likely consider charging access fees for devices on a per device basis for LTE-M and NB-IoT, or a combination of both, to better match the network resources consumed by these devices.

Hardware Simplification

LTE-M and NB-IoT both use simplified versions of regular 4G which reduces hardware complexity and cost once the technology is operating at scale.

GSMA maintains a list of modules that are commercially available at: https://www.gsma.com/ iot/mobile-iot-modules/ showing that the market for modules is fragmented into three main categories: modules supporting either LTE-M or NB-IoT and modules that support both LTE-M and NB-IoT.

LTE-M AND NB-IOT - GLOBAL AVAILABILITY AND OUTLOOK

Moving towards local availability in all countries

For global deployments of devices, enterprises need to take the life cycle of technology in consideration.

Global deployments need global availability, but new technologies are first locally available, typically in urban areas or with nationwide deployments. So when can we expect global availability for LTE-M and NB-IOT?

Today, the status for LTE-M and NB-IoT is that they are both locally available and on their way to becoming globally available.

We see that sometimes one operator in a region starts focusing on either LTE-M or NB-IoT, after which their competitors in the same region often offers the alternative.

We expect that in a few years both LTE-M and NB-IoT will be locally available in all countries.