Kris Oldland, Editor-in-Chief, Field Service News is joined on the Field Service News Digital Symposium by Dr Chris Raddats of the University of Liverpool a seasoned expert with experience from both the industry and academic sides of the aisle...

ARCHIVE FOR THE ‘the-view-from-academia’ CATEGORY

Jun 04, 2021 • Features • Digital Transformation • The View from Academia • Servitization and Advanced Services • EMEA • University of Liverpool • Chris Raddats

Kris Oldland, Editor-in-Chief, Field Service News is joined on the Field Service News Digital Symposium by Dr Chris Raddats of the University of Liverpool a seasoned expert with experience from both the industry and academic sides of the aisle centred around servitization, digitalisation and service marketing.

During the discussion, the two discuss a wide range of topics related to Raddat's sphere of insight including reflecting on the current learnings that are coming from a recent raft of academic literature.

In this excerpt from that full interview, the two discuss whether we are beginning to see servitization and advanced services reach a critical mass in the terms of momentum amongst field service focused organisations.

Want to know more?

FSN Premium subscribers and FSN Elite members can access the full-length interview plus many, many more in the Field Service New Digital Symposium. If you have an FSN Premium account you can access the video on the button below. If you are currently on our FSN Standard subscription tier you can upgrade your subscription by clicking the link below.

If you are yet to subscribe you can join 30,0000 of your field service management peers by subscribing to FSN Standard for free to gain access to a monthly selection of premium content or select either FSN Premium or FSN Elite for even more resources. Click the button above to visit our subscription page to find out more.

Further Reading:

- Read more about Servitization @ www.fieldservicenews.com/servitization

- Read more about Digital Transformation @ www.fieldservicenews.com/digital-transformation

- Read more about Academic Studies @ www.fieldservicenews.com/the-view-from-academia

- Find out more about participating in Chris's latest academic study @ research.fieldservicenews.com/current-studies

- Follow Chris Raddats on Twitter @ twitter.com/chrisraddats

- Connect with Chris Raddats on LinkedIn @ linkedin.com/in/chrisraddats

Nov 22, 2020 • Features • The View from Academia

Software-as-a-service has become well established, and recently a trend to sell Product-as-a-Service has emerged. PaaS is often sold in a similar way to products with limited additional services provided. From our perspective, this makes PaaS a...

Software-as-a-service has become well established, and recently a trend to sell Product-as-a-Service has emerged. PaaS is often sold in a similar way to products with limited additional services provided. From our perspective, this makes PaaS a rental service rather than a new form of servitization with value co-creation, as it reinforces an arm’s length relationship, Dr Christopher Ganz and Prof Dr Shaun West share their analysis...

Servitization and the concept of ‘Product as a Service’

Servitization is a current trend in industry, which aims to increase the service business volume in companies by offering their customers more, particularly more advanced types of services. Digitalization goes hand in hand with this trend and supports these innovations. Many of the benefits of digitalization come from collecting data that offers insights into the customer’s needs. Such insights and resulting actions can be beneficially offered as services. The links between servitization and product service systems (PSS) are not new and are shown in Figure 1.

Figure 1: The degree of servitization increases as we move to product-service system [1]

As part of servitization, many companies are currently advertising a variant they refer to as ‘Product-as-a-Service’. This is a machine rental agreement where the supplier keeps ownership of the asset and rents the machine to the customer. The customer is obliged to pay the 'rent' but not obliged to use the equipment. This analysis is similar to a real-option contract based on the "take or pay" concept. It means that the maintenance costs (and risks) are transferred to the provider, however, it lacks many of the aspects of advanced services associated with servitization. PaaS also keeps the relationship between customer and provider at arm's length and therefore does not align with the value-cocreation (and delivery) as defined by Service-Dominant logic. When we consider Tukker’s Product-Service System (PSS) framework (Figure 2), the positioning is within the "product-oriented" position, one step from the pure product although it does lend itself to positions further to the right.

Figure 2: The PSS continuum [2]

PaaS can’t be discussed without mentioning Rolls Royce’s ‘power by the hour’ concept. Apart from the fact that this concept dates back two decades, it is not example of PaaS as the asset is actually owned by a bank and leased to the airline that uses it. It is a way to buy the maintenance based on operational hours consumed on the machine and often includes value-adding aspects, such as swap-out engines and operational advice for the turbines.

Financial optimization

While a PaaS model is easily advertised, to set up a business model that actually creates value is not a simple task. In its essence, the PaaS model comes down to whose balance sheet the asset is on. In a traditional product sale, the product is owned and operated by the customer. All risks are with the plant owner. In its simplest form, PaaS is a rental or leasing agreement that changes the distribution (or shape) of the cashflows. The customer benefits from an improved Return on Asset (RoA), not by increasing the returns, but by reducing the value of the assets. This optimizes the KPI without addressing its intention, which is to increase the return. Furthermore, the value does not indicate that more can be done with fewer assets (e.g., improvements in operational efficiency), it’s doing it with someone else’s assets.

Such rental / leasing models are mostly done through financial intermediaries because the supplier is penalized in their balance sheet for carrying the customer’s assets. It is to be noted, that these services need to be accounted for financially. While the lower entry cost may look attractive for a customer, the repeated rental payments may finally sum up to far more than what the initial investment would have been. The total cost of ownership over the lifetime is generally required for a customer to decide whether such an arrangement makes financial sense.

Advanced services contracts

PaaS arrangements are cited in the context of advanced services, i.e., predictive maintenance, energy optimization, etc. Since the asset is still on the balance sheet of the supplier, it is in the supplier’s interest to keep it healthy. In fact, it should be in the interest of all stakeholders to run the asset optimally. Such advanced services can be framed as service contracts, regardless of whose balance sheet the asset is on. These service contracts can also be framed as performance-based business models, where the service supplier still has an interest to maximize the asset’s performance, even though they don’t own it.

Other services based on process support can also be integrated. Here, coffee equipment manufacturers have been successful in creating a range of value propositions to improve the availability of quality coffee. In a number of cases, they have done this by creating deeper relationships and partnerships with dealers and coffee shop operators. Other industrial examples have been Caterpillar who both sell and rent machines and support process support, asset efficiency services and, to some degree, process delegation services. Hilti also provides advanced services based on tool-box and Hilti-Connect models

Figure 3: Classification of industrial services can provide hints to how to build advanced services [1]

Pay per use

An expansion of the PaaS model, where the rent is paid by calendar time, there are other models that tie the payment to operation. Pay per use, pay per kilometer, pay per products produced are things being discussed. It is to be noted, that such models move part of the operational risk to the supplier without any influence on the operational decisions. It is of course in the interest of the customer to outsource some of the operational risk, but it is questionable whether the corresponding remuneration to the supplier is factored into such contracts. If not, this is surely not a commercially successful model for the supplier.

Xerox introduced the concept when providing copiers to companies, at a ‘per page’ expense. Customers bought the contract when photocopies were slow, low quality, and expensive. The rapid development of copiers led to a massive increase of photocopies over more than ten years. Swapping printers for more performant models was seen as a benefit by the customers, while the increased capacity of these machines led to more copies being made. While a customer may not have bought a new machine if they had owned it, Xerox benefitted greatly from providing the capacity to increase their own revenues by copying more.

Utilization sharing

One area where PaaS models make a lot of sense is when the utilization of an asset can be increased. A pay per use model makes sense if several customers can use the asset. A good example is cloud computing: a cloud provider can offer the infrastructure or platform as a service by giving a number of customers access to the computing infrastructure in a data center. Computing or storage capacity that is not utilized by one customer can easily be re-allocated to another customer. The utilization of the data center infrastructure is much higher in such an arrangement than if every customer buys equipment that covers their maximum capacity requirements.

For example, GE Energy offered a rotor access option to their advanced Planned-and-Unplanned maintenance agreements. For a fee, the customer gained access to a fully bladed rotor; this had significant value following a rotor failure, in effect providing a real-option contract to the customer. Additionally, taking the access agreement reduced the cost of insurance for the power producer.

Summary

Many PaaS approaches in the industry have failed, or do not provide a breakthrough in service revenues. We claim that this is mainly due to the misinterpretations we have explained above, that do not result in a positive business case for the supplier. Nevertheless, PaaS can offer advanced service delivery bases when integrated with other service-based concepts where use- or result-oriented value propositions are factored into the PSS continuum. Alternatively, it allows more creative value propositions based on process support services, asset efficiency services, or process delegation services.

References:

[1] (Based on Vandermerwe and Rada, 1988)

[2] Based on Tukker 2004

[3] based on Kowalkowski & Ulaga, 2017)

Further Reading:

- Read further academic commentary on the service sector @ https://www.fieldservicenews.com/blog/tag/the-view-from-academia

- Read more articles authored by Dr Shaun West @ https://www.fieldservicenews.com/blog/the-digital-twin-as-an-enabler-for-new-service-base-value-propositions

- Read more about servitization @ https://www.fieldservicenews.com/blog/tag/servitization-and-advanced-services

- Connect with Prof. Dr. West on LinkedIn @ https://www.linkedin.com/in/shaunwest/?originalSubdomain=ch

- Connect with Dr. Christopher Ganz on LinkedIn @ https://www.linkedin.com/in/christopher-ganz/

Oct 07, 2020 • Features • The View from Academia

Dr Shaun West of Luzern University of Applied Sciences and Arts takes a moment to share his latest work into where digital twins can bring data-rich insight that can drive active improvements in operational efficiency...

Dr Shaun West of Luzern University of Applied Sciences and Arts takes a moment to share his latest work into where digital twins can bring data-rich insight that can drive active improvements in operational efficiency...

The digital twin has stopped being a technology and is now becoming an enabler for new service-based value propositions, allowing us to understand the different options that exist and the consequences of them.

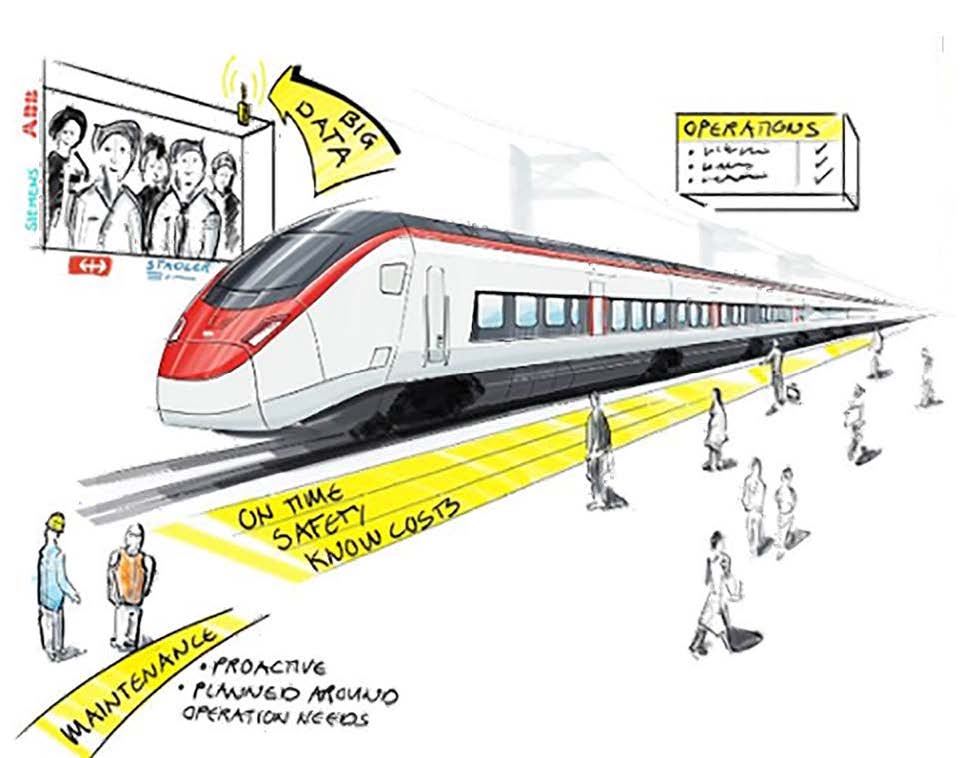

The twin does this by helping us to make sense of what is going on in a system, and supporting our decision making by translating the data into actionable information. Figure 1 shows a complex system based around mobility where we have many people active in the system, along with many machines and almost everyone wanting answers to different questions.

The digital twin allows us to combine data with both tacit and explicit knowledge to create new understandings from which new value propositions could be derived.

As part of an ongoing development project, we have been developing digital twins to support new solutions or value propositions that were not previously achievable. The cases were all complex and involved a combination of people and machines, also they were based on real-world cases rather than assuming new ‘ideal’ installations. This was challenging as it meant that the data quality was ‘messy’ and in some cases there was no live data – this is in-fact reality!

Figure 1 The digital twin can help many people with many different points of view

We first mapped out the problem space for each of the cases so that we understood the different people, the different situations that could exist, and the machines and possible data streams.

Do so, and you start to realize how little you actually know about people and their problems. One of the most powerful approaches we found, was to create a list of questions that people might need to address for different situations.

This helped greatly to describe the cases in detail before coding and supported the matrix describing different situations to be completed, typical

questions we found were:

- “How do I effectively match demand with capacity?”

- “Why do we lose production – we follow the OEM recommendations?”

- “What are the “real” costs of production?”

- “How long will this job take?”.

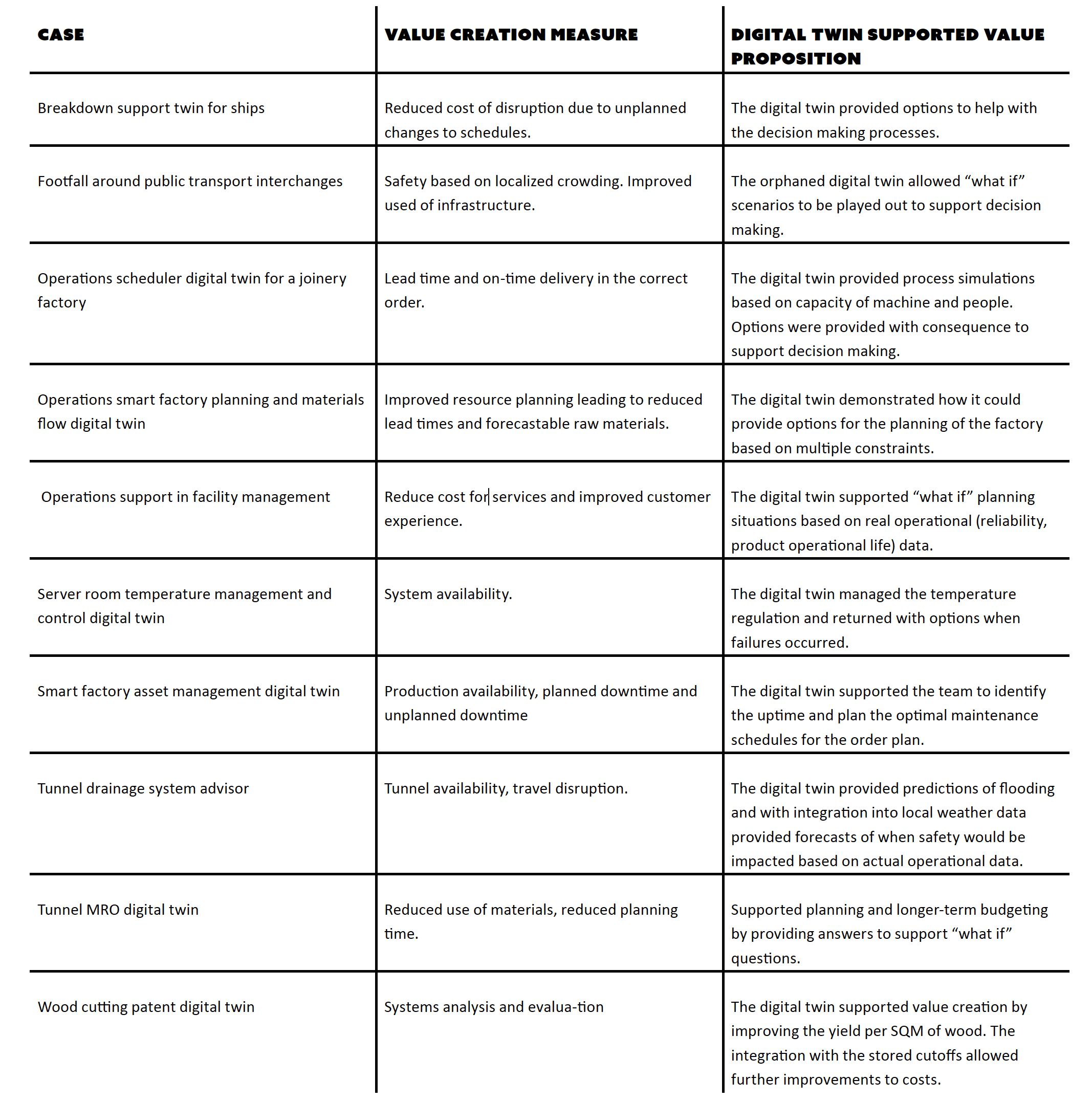

The Ten Use Cases in Detail

Based on the problem space descriptions, we then started to code the digital twins (mostly based on agent-based modelling) and at the same time detailed out the value proposition.

For each case the purpose and the value propositions provided will be described, along with the main source of customer value. Interestingly, all of the twins developed contained aspects of value co-creation. All were developed off-line using real or manufactured data to support the simulations – even with just the simulation data the digital twins provided additional insights that support decision making.

- Breakdown support twin for ships – the twin mimics the current status, allowing drill-down to individual ships and the subsystems within each ship. The twin then supports decision making for planning and scheduling routes based on actual status and unplanned corrections. The value is derived from the reduction in disruption when changes occur and understanding the loss of operational availability associated with unplanned events.

- Footfall around public transport interchanges – the purpose is to better manage the flows of individuals around a station based on the current and future station layout and train schedules. The value comes from improved traveler safety through the re-platforming of trains and/or investments in new walkways or simply better placed signage to improve flows.

- Operations scheduler digital twin for a joinery factory – the purpose was planning optimization around a production process with bottlenecks in individual competences and machine capabilities. The main source of value is efficient production planning, with known delivery dates and costs.

- Operations smart factory planning and materials flow digital twin – a system capability twin matched demand to support the development of a dynamic operations planning twin. The main value is from the provision of planning support for the ‘optimal’ production schedule, and for creating an agile planning tool presenting the cost of changes along with a different planning solution.

- Operations support in facility management – the digital twin provides operations support for Facility Management (including routine maintenance, planned maintenance and unplanned maintenance). Value would be created from reduced spares holding and faster task scheduling and cost estimation.

- Server room temperature management and control digital twin – the purpose of this twin is to improve overall equipment up-time and provide further business stability through equipment risk mitigation. Value accrues from operational support, temperature stability, and routine reporting.

- Smart factory asset management digital twin – the purpose was planning, to support the different models of maintenance and operation to find the required compromises between different demands. It also allows new equipment to be integrated into the system to simulate outcomes based on different configurations. The value is created from an agile O&M schedule, allowing run-ons to be examined for additional maintenance costs. Additional value comes from improvement plans for modifications to improve factory performance.

- Tunnel drainage system advisor – the purpose of the digital twin is to monitor the water levels and give predictions based on the weather conditions and other factors that influence the water level in the tunnel. The value comes from keeping the tunnel safe and operational, measured by performance.

- Tunnel maintenance, repair and overhaul digital twin – the twin supported maintenance service delivery by improving planning of maintenance and increasing the efficiency of field service engineers.

The main source of value from the digital twin was identified as keeping the tunnel operational, with an availability metric to measure performance of the MRO team.

Two of the value propositions built are now in the process of being sold to customers. The detailed understanding of the problem and the value creation (and destruction) has helped establish the sales process and the pricing structures. The input from the launch customers has been useful in helping to validate the value proposition, and in some cases resulting in an improved value proposition based upon their real-world feedback.

The value propositions would not have been possible without the underlying digital twins, the simulations and the detailed problem space descriptions.

What should you do if you want to create new value propositions enabled by digital twins?

To help you, we recommend three things that you could do to help your organisation, based on our insights from the study:

- Spend time to describe the problem space from many different points of view and in different situations.

- Use real questions driven by customer issues to help you clearly define the situation and the outcome that the people are expecting.

- Develop the value proposition together with a launch customer.

What are we doing to help with the design of digitally enabled value propositions? We are collating the lessons from the project and creating a playbook to help organisations understand the problem space in depth. This will help guide them how they could model the system and then provide hints and tips on possible value propositions.

Acknowledgements

I would like to thank Oliver Stoll (oliver.stoll@hslu.ch) and Petra Müller-Csernetzky (petra.mueller-csernetzky@hslu.ch) and for providing valuable input into the study. The study was co-financed by Innosuisse (Project 35258.1 IP-SBM) and delivered in partnership with ten partners and led by Jürg Meierhofer (juerg.meierhofer@zhaw.ch).

Further Reading:

- Read more about digital transformation @ www.fieldservicenews.com/digital_transformation

- Read more articles from Dr West @ https://www.fieldservicenews.com/blog/author/shaun-west

- Read more articles from academia @ https://www.fieldservicenews.com/blog/tag/academic

- Connect With Dr West on LinkedIn @ https://www.linkedin.com/in/shaunwest

Jul 15, 2020 • Features • Advanced Services Group • manufacturing • Professor Tim Baines • The View from Academia • Covid-19 • Servitization and Advanced Services

Professor Tim Baines, Director of the Advanced Services Group, Aston University and Dr. Ali Zia Bigdeli, Senior Lecturer in Industrial Services Innovation at Aston University argue manufacturing should embrace services as part of its post-COVID-19...

Professor Tim Baines, Director of the Advanced Services Group, Aston University and Dr. Ali Zia Bigdeli, Senior Lecturer in Industrial Services Innovation at Aston University argue manufacturing should embrace services as part of its post-COVID-19 strategy.

Change, a 1985 paper argued, can be characterised as a “punctuated equilibrium”: long periods of relative calm and small incremental alterations that are interrupted by brief, but radical, seismic shifts. COVID-19 means that we are now living through one of those revolutionary moments.

Advanced Services and Positive Business

But that also means that there is an opportunity to look at things in a new way. For the past 20 years, we’ve been conducting research and advising manufacturers to compete through services – activities aimed at solving customers’ problems – rather than simply just pushing boxes out of the factory.

And our reasons are simple: services are good for business, good for the economy and environment, and good for society. Now accounting for 80% of the UK’s economic output, services have grown by 30% over the past 20 years. By comparison, gross domestic product (GDP) generated from selling products has contracted – a trend that is being replicated in every developed economy across the world.

But it has been a slow and sometimes painful journey – “What is this thing called servitization,” we are asked. “And how do you spell it?!” Up until now, change in this field, like in so many others, has been evolutionary, somewhat incremental and exploratory. But then arrives a global pandemic that shatters the equilibrium and stimulates radical innovation.

These are challenging times, and it’s important not to make light of the struggles facing the global economy. Business activity is currently polarised around sector and geography. On the one hand are manufacturers who support the food and health sectors and have never been busier. On the other are those businesses linked to the aerospace, automotive, and oil and gas industries which are being forced to mothball facilities and lay off staff in their tens of thousands.

For some, the implications are so severe that they may not survive. Even those that are doing well are having to deal with a reduced workforce, social distancing in the workplace, and the economic fallout of customers being unable to pay their bills.

Disrupting the old norms

How appealing the old norms may now seem. Until just a few months ago, most executives within manufacturing organisations had a rather passive, established view of services. For us, it was frustrating, but comfortingly familiar.

We could work with these manufacturers to help them better understand the value of services, influence key decision-makers and then hopefully get a chance to support their innovation of new business models, technologies and organisational structures. But we often experienced an equilibrium – the harder we helped manufacturing executives to push for more services, the harder the system pushed back.

Now, however, that equilibrium is being disrupted.Take performance advisory services. These are services that allow manufacturers to use digital technologies to gain insight into how customers use their products, and then offer data and/or intelligence back to that customer on how to gain more value from those products.

"The end of this period of disruption will bring a new set of norms, and it’s beyond belief that we will return to the days of simply shifting boxes..."

An example of this type of service is Siemens’ monitoring of the condition of airport baggage carts. The company gathers acoustic and vibration data from rail-mounted luggage carts around the airport and uses this data to assess the likelihood of breakdowns before they happen.

Breakdowns cost time and money. So spotting potential breakdowns in advance saves airport operators the penalties that must be paid when luggage isn’t loaded onto flights on time, and improves the passenger experience through the punctual delivery of baggage.We have seen a wealth of technically excellent digital systems like this. Most, however, have so far failed to be commercially viable and manufacturers have been reluctant to invest in and push them to customers. But in the current climate, that may change.

As well as opening up a huge new market opportunity, these services could be far more profitable than simply selling the products themselves. Such services can also develop enviable intimacy with and loyalty from customers as the provider is able to address their customers’ demands and problems much more quickly and effectively.

And now times are changing, the economic potential of services is becoming more visible. Indeed, remote support and performance advisory services – helpdesks, remote support for breakdowns, digital installations – provide obvious solutions in an age of social distancing, remote working and lockdowns.

Customers either want remote advice on how to fix problems themselves, or they want the manufacturer to remotely fix and upgrade their equipment. It’s not all about technology, of course – customers still value speaking to a person, just not face to face. But manufacturers no longer need to gamble as much on selling these new systems; customers actively are seeking them. Both parties are starting to look at the bigger picture, and services are proving vitally important to both.

Accelerated change

For some time yet, change will be accelerated and hastened. The end of this period of disruption will bring a new set of norms, and it’s beyond belief that we will return to the days of simply shifting boxes. At the very least, business plans will need to include how to deal with disruption – whether it’s related to health, the economy or the environment.

The opportunities that this creates for services are potentially dramatic. Services are in the midst of radical change and, of course, we all look forward to returning to those long periods of relative calm. However, in so many ways, things will never be the same. Business models for manufacturers will have been disrupted, and there will be new and different conversations about the value of services. These business models have the potential to deliver huge value, and a level of resilience that we may never see again for production-based ways of competing.

Further Reading:

- Read more articles by Tim Baines @ https://www.fieldservicenews.com/tim+baines

- Read more articles by Ali Zia Bigdeli @ https://www.fieldservicenews.com/AliZiaBigdeli

- Find out more about the World Servitization Conference @ https://www.advancedservicesgroup.co.uk/wsc2020

- Read more articles about servitization @ https://www.fieldservicenews.com/servitization

- This article first appeared The Conversation.com here

- Follow the work of the Advanced Services Group @ www.advancedservicesgroup.co.uk/

- Follow the Advanced Services Group @ twitter.com/theasgroup

Jun 15, 2020 • Features • The View from Academia • Servitization and Advanced Services

Professor Shaun West of Luzern University uncovers some of the fundamental barriers manufacturers face when trying to implement a servitization strategy.

Professor Shaun West of Luzern University uncovers some of the fundamental barriers manufacturers face when trying to implement a servitization strategy.

The development of new services is not like new product development and here starts the problem in many manufacturing firms (Figure 1). It creates a significant disruptive change to the business – it is a change management process, and it is a journey.

Servitization may be a 'good move', But it is a complex undertaking...

Strategically, management generally likes the idea of service because customers ask for it and because margins are higher than in traditional product sales business. Given that customers want it and it has good margins, “senior management’ generally considers servitization a good move, without first understanding the challenges and the underlying barriers that could slow the journey into service.

(Figure1: Differences between service- and product-based business)

The journey to services is often bumpy, and we have seen that services are not the same as products. Most of the value is created from the intangible aspects of the service, making it hard to identify and measure. Manufacturing firms often find it harder to deal with the intangible elements of services. For them, it is easier to measure metrics such as “on-time delivery” rather than “customer satisfaction” as they value hard facts more than soft facts (Table 1). Andy Neely and his research term provided a framework that helps us to identify the barriers that stop us from making the switch to services and categorized servitization barriers into seven categories.

(Table 1: Differences between technology- and service-based firms)

We dug deeper to understand the specific challenges and learnt more via a series of surveys and interviews. We found there were common challenges that leaders had faced within each of the barriers. The good news is that that, in general, you are not alone. The downside is that contextual issues mean most transitions are unique as they have different starting points and different visions. Assuming that the firm has made the strategic decision to deliver services, then you need to understand the market readiness, the strategic fit, and the firm’s cultural context. Building the longer-term business structures (e.g., a business unit with its own P&L) is critical, and without this, there is limited long-term sustainability.

Resources need to be freed up for both service innovation and delivery; without budgets, nothing will ever happen. This also means that you need to develop and embed service processes, these are likely to be very different in detail to the processes that your manufacturing colleagues use, and this will create conflict, often because with services you work on a customer’s site together with the customer. Given that services are co-created and delivered with customers, engagement has to be proactively managed, and trust built so that you can continually innovate with your customers and improve customer experience.

Observation of the implementation-based barriers to servitization

Based on 40+ interviews and survey data from over 150 individuals, we tried to clearly describe the observations that slow or prevent the implementation of a servitization strategy. We start by providing some quotes (Table 2) from people who have been directly involved in a transition before giving a summary of the best practice as we view it at this time. In our servitization study, we quantified and ranked them the barriers in order of importance based on the input from the surveys.

Based on 40+ interviews and survey data from over 150 individuals, we tried to clearly describe the observations that slow or prevent the implementation of a servitization strategy. We start by providing some quotes (Table 2) from people who have been directly involved in a transition before giving a summary of the best practice as we view it at this time. In our servitization study, we quantified and ranked them the barriers in order of importance based on the input from the surveys.

(Table 2: Main barriers to servitization)

The move to ecosystem innovation is essential for the servitization journey when we consider the competition, suppliers, and partners. This is a significant change for firms as customers and agents can become important partners, and in some cases, competitors may become customers. Localization aspects are essential, and this depends on the size of the company – a large firm is different from a small firm. Local rules (or norms) can create barriers to service delivery, finding local partners can reduce costs and limit others from entering the market. It is important to learn to work and use customer pull to support servitization; some of your best supporters for servitization are your customers.

In many cases, they will champion your innovations and provide opportunities for prototyping ideas and helping you convert them into new value propositions. They will also support you with pricing signals and provide insights into new revenue models. Customers are critical to sales growth (clearly!) and margins. In service, the long-term retention of customers is recognized as a crucial success factor for both the service and equipment businesses.

As you grow your service business, sharing of knowledge and information about the services in action and your customers’ processes becomes more important. Information sharing needs to be managed within the service business as well as to the equipment business, and there are more customer touchpoints with service than with an equipment business.

Providing the information gathered as feedback to the equipment business can also reduce servitization barriers. There is often a push to move to advanced services, but basic data and understanding is required before moving to more advanced product-service systems – moving too soon to advanced services as a way to hide your weaknesses in service delivery can kill the service business.

Finally, businesses must have their own P&L and the support of HR to deliver the change because of the difference in processes and organizational culture.

What you can do to help with the shift to services

To help you, we recommend three things that you could do to help your firm, based on our insights from the study:

- Open your mind and that of your colleagues to the differences between a product-business and a service-business. They are not the same, even if the underlying equipment is the same.

- Focus on your customers, learn how they use the equipment, and how and where you can support them. Listen to them and allow them to support your service innovations.

- Empower your service teams to deliver the service projects and ensure that the P&L contribution is recognized by the firm.

What are we doing to help with the transition? We are currently working on a book to support the shift to services in a practical way, basing the book on cases and providing examples of tools that we have seen being used to help product-based firms make the transition successfully.

Acknowledgements:

I would like to thank the following for providing valuable input into the study.

- Paolo Gaiardelli (paolo.gaiardelli@unibg.it),

- Nicola Saccani (nicola.saccani@unibs.it),

- Ali Bigdeli (a.bigdeli@aston.ac.uk),

- Tim Baines (t.baines@aston.ac.uk)

- Peter Alexander

Further Reading:

- Read more articles by Shaun West @ https://www.fieldservicenews.com/Shaunwest

- Read more articles on servitization @ https://www.fieldservicenews.com/servitization

- Read more articles by Tim Baines @ https://www.fieldservicenews.com/Timbaines

- Read more articles by Ali Bigdeli @ https://www.fieldservicenews.com/AliBigdeli

- Find out more about the World Servitization Conference @ https://www.advancedservicesgroup.co.uk/wsc2020

Jun 08, 2020 • Features • Advanced Services Group • The View from Academia • Covid-19 • Servitization and Advanced Services

Aston University’s Professor Tim Baines reflects on how the impact of the coronavirus pandemic has meant that he has had to re-evaluate his predictions from 2019 as industries rapidly pivot and shift their priorities and why servitization has a role...

Aston University’s Professor Tim Baines reflects on how the impact of the coronavirus pandemic has meant that he has had to re-evaluate his predictions from 2019 as industries rapidly pivot and shift their priorities and why servitization has a role to play in that recovery.

People don’t like to admit their mistakes and professors are no different. Indeed, we like to believe that we give more attention to the science anfacts than others may do. But I was wrong. Late last year, I wrote a piece that predicted that the three priorities for manufacturing business in the 2020s would be about responding to the challenges of poor productivity and climate change, and grasping the opportunities of digital.

Servitization's role in Covid recovery

I think it’s now quite safe to say that although these will remain important, priorities will shift towards the recovery of the economy – in particular the recovery and rebuilding of industry large and small. I also think that we will start to pay more attention to embedding greater industrial resilience, in an attempt to insure against similar disruptions in the future. It’s early days, but how might we do this?

My earlier judgment seemed sound at the time. I based my prediction on what I saw, was told and read about. I rationalised that there were three principal forces driving change, and my logic went something like this:

The UK, among other western economies, has an historical problem with productivity, we work too many hours to generate the level of wealth we create and this adversely affects growth something that everybody is keen to address. The evidence of climate change is becoming more acute; it can be seen in the melting ice sheets in Greenland and raging bushfires of Australia.

Customers and consumers are becoming more sensitive to the environmental impact of consumption, and supply chains are being restructured. Meanwhile, digital innovation is all around - whether you see it as IOT, Industry 4.0 or simply a new App - and its adoption within industry is being widely advocated.

What my logic did not account for was the seismic shock of a pandemic. Business has changed in a way none of us could have foreseen; borders have closed, travel is banned, staff are in isolation, society is in lock-down, working from home is the new norm and the kids are off school! Business activity is polarising; some factories are being mothballed, while those that service the food and healthcare sectors, for example, are exceptionally busy. Indeed, governments are intervening in ways unimaginable since, in many countries, the Second World War. At this time, I know it’s difficult to look beyond the next few weeks, but it is important to look forwards, albeit with a little care and sensitivity.

"Resilience is key and business models based around services are more conducive to achieving this..."

Economic activity is essential and it must recover. Undoubtedly, there will be many government initiatives to kick-start the economy, but how do we rebuild the manufacturing industry to be more resilient to future shocks, whether these shocks are health-related, trade-related, or indeed from the adverse effects of climate change. Quite clearly, the same as before is not sufficient. We have a unique opportunity to move industry forward and adopt business models that are better-aligned with the new world we will enter.

The 1900s and early 2000s were dominated by production-consumption business models, exemplified by mass production, Henry Ford and the consumer society – make, sell, dump. Feeding a growing world population, ruthless in its consumption of resources, servicing hungry global markets and all too often insensitive to the impact on the environment. This was not sustainable, and now many sectors have ground to a halt.

While mass production of course is still alive across some sectors - food and medicine to name a few - in other sectors this lockdown has shown that we do not need cars, airports and shopping centres to the extent we used them. As such, there is a great opportunity for services, delivered remotely and consumed locally, which help to build the quality of our lives without the need for consumption. If industry can build new business models on this basis, we will also create a truly resilient economy.

So, I believe that resilience is key and business models based around services are more conducive to achieving this. But what could such services look like in practice? In my next blog, I will reflect on some of the businesses that are making great progress in this space.

Further Reading:

- Read more articles by Tim Baines @ https://www.fieldservicenews.com/timbaines

- Read more on servitization @ https://www.fieldservicenews.com/servitization

- Read more about Covid-19 in service @ https://www.fieldservicenews.com/covid-19

- Read more about the Advanced Services Group @ https://www.advancedservicesgroup.co.uk

- Read more about the World Servitization Conference @ https://www.advancedservicesgroup.co.uk/wsc2020

May 11, 2020 • Features • Digital Transformation • Shaun West • The View from Academia

Dr Shaun West of Luzern University offers us some insight into the barriers to digital transformation - one of the biggest areas of focus within the field service sector globally...

Dr Shaun West of Luzern University offers us some insight into the barriers to digital transformation - one of the biggest areas of focus within the field service sector globally...

I believe digital transformation is difficult for manufacturers to design and develop, before considering its execution or delivery. I will draw from published materials, an unpublished survey and study, and personal experience to help understand the challenges we face, and suggest realistic actions firms can use to help them overcome the barriers and develop new value positions and solutions.

The motivation for our research came from a Swiss study that identified the drivers, barriers and risks for digital transformation (Figure 1 below).

The Need for Digital Transformation:

Why do we need to make this transition? Within a Swiss context, a recent survey by Swissmem confirmed the importance of the development of new digital solutions. The Swiss State Secretariat for Education, Research and Innovation report “Research and Innovation in Switzerland 2020” expanded further: they anticipate “that future revenue models for these new digitally enabled solutions will be mainly driven by data and platform exchanges and will become output focused (e.g., pay-per use)”. It is clear that even in an economy focused on manufacturing there is an ongoing shift from a goods-dominated world to a services-dominated world.

Reading the newspapers, it would appear that digital transformation is all about technology and within ten years we will all be out of jobs as robots and AI will have taken over. Read beyond the hype, and it becomes clear that the development of new digital solutions within a product service system environment is as much about organization change as technology.

"Digital transformation has a wider impact than most companies see, and this creates barriers within firms..."

Much of the new technology will allow us to redesign our current work and the way in which we deliver it. Netflix evolved from a DVD subscription model based on postal services to an internet-based model. As Netflix evolved, they removed the physical material from their system, improved the efficiency of the service delivered, and increased the value in their offer (anyone who watched UK television in the 1970s would be amazed by Netflix today).

Digital transformation has a wider impact than most companies see, and this creates barriers within firms. Digital has a clear impact on production (e.g., MES, ERP), IT (e.g., cloud services) and marketing (e.g., big data behaviour insights), but it has a hidden impact on other parts of the business, often in unexpected ways (e.g., your customers have more information on status than your service personnel). Perhaps a better way to view digital’s potential impact is to consider the technology, people and processes involved. Think how we moved to faxes, then email, then to WhatsApp, now to Zoom and workflows; we have absorbed each new technology and changed processes and our behaviours, as Table 1 shows.

Examples of the digital transition:

Before examining our survey in detail, it is useful to consider some cases. Table 2 gives insights into a range of firms and the barriers they encountered: Piaggio is undergoing a servitization journey with a product-centric mindset; Kone have wide range of technologies within their installed base; FAVI’s workforce resisted empowerment; Unilever built their own data-lake with a massive amount of data; Mass Mutual moved to real-time fraud detection; Domino’s integrated production technologies into a manual process; Cannon faced challenges connecting machines; Allianz moved from operational silos to a process driven business. No firm is alone in the digital transition, many face similar challenges, and all firms should look to others for lessons.

Survey and interview insights

We conducted a survey with 124 respondents from different-sized firms, the majority (+90%) of which were industrial. Most information was provided by middle management, with over 2/3 of the respondents being from the firms’ headquarters.

When we asked what was driving digitization in each company, we discovered firms wanted to improve internal process efficiency, develop new customer value propositions and use both to deliver new business models. Some companies expressed concerns with hiring Gen-Y or millennial staff, as they felt they were “somewhat old-fashioned and not an attractive employer” but they confirmed they needed Millennials. We were concerned that many firms were only interested in internal efficiency improvements, rather than wishing to build new digitally-enabled value propositions.

The barriers firms were facing were based around weak/no vision from the leadership, existing/legacy IT, the lack of skilled talent, and general resistance to change. Lack of vision from leadership was considered a major barrier, the interviews showed flip/flopping with direction and application of digital was an issue.

"The lack of skilled talent matches with the lack of leadership vision: how can you hire the right people when you have no clear vision?"

I have some sympathy for this as it’s hard for a second-tier manufacturer to be able to create a clear and viable strategy and vision when it comes to digital – just look at the challenge VW Group are facing today with this. Existing IT systems were considered next most important, as in the new world IT skills become core to value creation and capture, rather than just being a business cost. The lack of skilled talent matches with the lack of leadership vision: how can you hire the right people when you have no clear vision? Resistance to change and an organization’s silo mentality cannot be broken without clear leadership.

Respondents strongly agreed that business development should lead the digital transformation, as it’s not a technology development program but rather a business and cultural change program that has impacts across the business. Treating it as an IT project means it will fail; treating it as a technology play means it will fail. Treating digital transformation as a change management program (that is even more transformational internally and externally than Lean) means it may well succeed.

The respondents confirmed that digital will impact on all areas of the business, however service was considered to be the area most affected. Most thought the firm’s internal infrastructure would be impacted, and this is one of the most visible aspects of the transformation– in effect the whole business will change.

Over 330 individual comments were left by the respondents, demonstrating how important this topic is to the community. Analysis showed that ‘people aspects’ were more commonly mentioned (80%) as barriers to a successful digital transformation:

- Strategy: lack of vision & mission from the leadership, transformation roadmap.

- Leadership: resources, sponsorship and management conception, and fear of losing power

- Culture: customer centricity, openness and willingness to change, silo management, hierarchy vs network.

- People: capabilities, expertise, roles, adaptability.

- Governance: communication and collaboration, KPIs, alignment.

- Middle management: as a key role between leadership and workforce.

- The workforce: knows that they need to update, but Leadership does not understand where to start.

- Education: is key for long-term sustainable implementation.

- Digital transformation never starts at C-Level: provide evidence that it can be profitable

- Build teams – members must have digital skills, flexibility (intellectual) and the capability to do abstract work.

Technology must always be applied in tandem with effective, well-designed processes. These converge into a “single system” where data is shared, processed, and integrated across the organization. Technology and process barriers (20%) were based around:

- Automation and connectivity (ICT infrastructure, cyber-physical products).

- Intelligence (processing and analyzing data).

- Operations, supply chain, product lifecycle (channel and business practices/processes, agility, Integration and data exchange).

- Select a technology that fits with your value chain.

- No technologies are perfect.

- Missing customer voice: Involvement of customers in product development.

When it comes to implantation in the business, we found that:

- Legacy systems are a barrier: How to digitalize all company levels? Not only buy technology but adapt products and processes accordingly.

- DT costs money and time.

- New jobs/ functions as a DT consequence.

- Start small, and if it works, go ahead; if not, change strategy.

Companies must adapt their organizational structures and processes to allow their workforce to drive and deliver Industry 4.0 initiatives. This must be done within a clear vision set out by the leadership. Some new ways of working will fail, and some will be successful. The lessons learned need to be openly shared within the firm. Companies should encourage cross functional and cross business collaborations on smaller projects rather than large formal “IT” projects which generally lack long-term business impact. The overview of the transformation should be led by business development and be close to, but separate from, the operational business.

Teams need to try out new technologies, such as cloud computing and machine learning. Assets and equipment need to be integrated with the enterprise system, to monitor and analyze the performance on both a technical and an operational base. As processes within production, services, sales, supply chain and the product lifecycle become integrated, they will converge allowing data to be shared, processed, and integrated across the business. Figure 2 (below) provides graphically the complex environment in which we live and the considerations we have to take when designing Smart digitally-enabled services.

How can you help your firm overcome barriers preventing digitalization?

Knowing where to start isn’t easy, however the survey sheds some light on the barriers preventing or slowing digitization. Our view of the future is shown in figure 3 (below)and knowing where you and your firm sits within this ecosystem is the key. Three ways you could help your firm, based on our insights from the study:

- Develop a digital strategy, vision and road map for your team or business and communicate it clearly inside and outside the team. Ask at every team meeting how digital will impact and change the business and discuss opportunities and risks.

- Use small mixed teams to develop digital solutions with impact within the firm. Learn from these teams what works and what doesn’t in your business environment.

- Share your digital lessons learnt from the projects within the firm, with your customers and your suppliers. Work with suppliers to improve operational efficiency: work with customers to develop, prototype and test new digitally-enabled solutions and value propositions.

Acknowledgements

I would like to thank Lucerne University of Applied Sciences and Arts for providing the funding for the study as well as my colleagues (Günter Zepf, Ute Klotz, Barbara Kummler, Pilar Gil Fombella and Paolo Gaiardelli).

Further Reading:

- Read more about digital transformation @ www.fieldservicenews.com/digital_transformation

- Read more articles from Dr West @ https://www.fieldservicenews.com/blog/author/shaun-west

- Read more articles from academia @ https://www.fieldservicenews.com/blog/tag/academic

- Connect With Dr West on LinkedIn @ https://www.linkedin.com/in/shaunwest

Apr 09, 2020 • future of field service • Lucenre University • Servitization • Shaun West • The View from Academia • Servitization and Advanced Services

Dr. Shaun West, of Lucerne University, explains why increasingly it seems that we have made the mistake of designing services with the machine in mind and us mere humans are developing a habit of just getting in the way...

Dr. Shaun West, of Lucerne University, explains why increasingly it seems that we have made the mistake of designing services with the machine in mind and us mere humans are developing a habit of just getting in the way...

I don’t like to be treated as a cog in a larger wheel and so why do we often design systems that treat us as if we were a cog in a complex system? This has been to me often a contradiction we see in the modern world where services are more and more standardized so that we feel we are there to service the machine.

The Importance of Service Design

My recent trip through Heathrow was very much in that vain – services (often hidden services) have been dehumanized that the experience for all actors involved is very poor.

Agency within the system at Heathrow has been lost for all actors leading you to consider that sheep might have a better experience, but at least the system is cost-effective and compliant. But service science and through service design, we don’t have to design the future world like this - we can and must do better.

We are trying to look at things in a more human-centric approach with our Smart Twin’s project where, with ten partners, we are building digital twins for different use cases. Within a number of the cases, the interactions with the digital assistant are really important as they are supporting decision-making processes.

In other cases, we’re considering how to delegate important tasks to the digital assistant and expecting them to return for new instructions when problems start to build. This is a very different position from asking Siri to find the music I’ve been listening too (Nylon Strung by Underworld if you were interested) or to tell my heating system at home to change the set-point to 19°C from 14°C.

This returns us to the thought that “we need to remember that the human is part of the system rather than subservient to the system”. Given that many of us are in the more technical environment, it is worth looking at how we used to treat machines – we gave them care and attention, we looked after them and we listened to them.

In effect, we treated them as if they were human in many aspects. This was part of the logic that we initially used with the development of the Avatar model. (See figure 1 below). To keep the truck working for me I have to look after it and treat it with respect, if I don’t it will stop doing what I expect of it.

The model shows graphically what you need to do for it and what it will do for you – over the life-cycle you can see the whole range of services that it needs to consume to deliver for you. My coffee machine behaves just like this – if I don’t fulfil my side of the bargain it delivers me poor coffee.

When digitalization takes place we automate jobs so, therefore, people just resist the change. How true is this really? It depends… robotic or digital service assistants can be deployed.

The ‘self-service kiosk’ service assistants can, in product dominate logic, appear to be a major step forward on the service. It becomes possible to have one “service operative” whose real job appears to tell me how I should be interacting with their new solution rather than allow redeployment of staff to improve the overall customer journey and experience.

In a case I know well, the digital assistant does this by taking away tasks that the current service desk operators are poor at performing and allowing them to focus on supporting the customer with real issues – the objective of the service desk.

Here the service desk didn’t want to go back to the old way of working. Interestingly, they are now happier in their work and doing a better job.

The common theme here is to focus on all people and machines with respect and understand their basic needs and requirements, as well as what you're expecting from them when building digital solutions.

Agency is important for people; this places us in ‘control’ and allows us to have some control and understanding of what is happening. It stops us from feeling like being a small cog in a large complex wheel. Agency also brings co-creation of value, again important as the literature confirms that lasting relationships are built on co-creation of value and joint decision making between many actors.

Such relationships also create social and emotional value during service engagements and somehow we need to learn to do this effectively with digital helpers, assistants, and advisors.

Dec 09, 2019 • Features • future of field service • Servitization • The View from Academia • Servitization and Advanced Services

Chris Raddats from the University of Liverpool and previous guest on the Field Service Podcast looks forward to the issues that might dominate the servitization agenda over the coming years...

Chris Raddats from the University of Liverpool and previous guest on the Field Service Podcast looks forward to the issues that might dominate the servitization agenda over the coming years...

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply