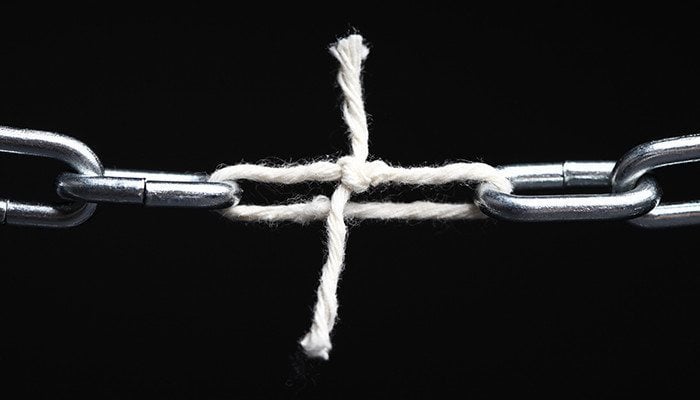

Technicians, customers, spare parts and profits: How strong are the links in your supply chain?

May 13, 2016 • Features • supply chain • Syncron • Uncategorized • Parts Pricing and Logistics

Giacomo Squintani of parts management specialists Syncron looks at the challenge of ensuring your supply chain is not the weak link in your field service delivery...

As the overall experiences customers have with durable goods manufacturers become more critical to company success, the strides made in field service management to ensure these positive brand interactions have been remarkable.

Field service technicians not only are the ‘face’ of a company – the individuals interacting with customers on a regular basis – but also key stakeholders in improving performance for the business as a whole.

As a service manager, you must put yourself in both your customers’ and your technicians’ shoes. Your customers’ experiences have improved greatly in recent years. You’ve reduced response times and improved the accuracy of the timing of your technician’s visit while improving first time fix rates. You’ve empowered them with the guidance to fix many problems without visiting them in-person, saving everyone time and money.

"Field service technicians not only are the ‘face’ of a company – the individuals interacting with customers on a regular basis – but also key stakeholders in improving performance for the business as a whole."

But, what’s the classic problem that frustrates your customers, your technicians and you as a manager?

That’s right. The technician is on time, highly knowledgeable and determined to help, but isn’t stocked with the correct part.

So your brand’s main ambassadors are all too often left sinking in unsatisfactory excuses as unhappy customers stare and shake their heads. And suddenly, that value you’d created through field service management technology investments is compromised by insufficient part availability.

The problem

Many OEMs have successfully grappled with the age-old parts:people challenge, and are reaping its many benefits.

In 2013, AberdeenGroup established that only 45 percent of the companies they interviewed had “increased their focus on service parts management as a result of the added demands from customers to improve service-issue resolution”[1]. Why are so many organisations failing to address a problem that impacts technicians’ effectiveness, brand reputation and customer loyalty, tying up cash in vans and warehouses in the shape of unnecessary, often obsolete stock – ultimately harming profits?

"Why are so many organisations failing to address a problem that impacts technicians’ effectiveness, brand reputation and customer loyalty..."

In a separate report, WBR established that, when establishing the criticality of future investments, only 8 percent of executives were considering inventory management.

Yet, when they examined the sources of customer complaints, the biggest contributing problem was parts unavailability, cited by 55 percent of service executives. Failure to fix the issue on the first visit, the engineer’s arrival time and their lack of experience generated far fewer complaints, with rates of 35 percent, 29 percent and 12 percent respectively[4]. These negative experiences leave your customers baffled and frustrated with a negative perception of you brand.

The solution

Resolving these types of customer issues and experiences is perfectly feasible.

Technologies exist for this very purpose – service parts management and scheduling solutions interacting together to ensure that when your technician arrives to the right place at the right time, they have the right part to keep your customers happy and encourage repeat business.

"Service parts management can make your technicians’ lives easier, and in turn positively impact each customer’s experience with your brand."

Service parts management can make your technicians’ lives easier, and in turn positively impact each customer’s experience with your brand.

As outlined previously, technicians’ responsibilities are broadening: their job no longer ends when the issue is resolved, it entails acting as trusted advisors, identifying opportunities for further business and potentially maintaining other vendors’ equipment. And, most importantly, are the ones interacting face-to-face with your customers.

Room for improvement

Service part inventory networks are complex – a part may go through central warehouses, distribution centres, regional stocking locations and secure local collection boxes along its journey to a technician’s vehicle. Oftentimes, technicians will end up being over-stocked, causing unnecessary restocking at the warehouse.

Hurt by online shopping, brick-and-mortar retailers are providing spare part stocking locations to bridge the physical gap between technicians and end customers.

"You owe it to your technicians to empower them with the right tools for the job."

With switching barriers lower than ever, in a competitive landscape where you are not only fighting rival OEMs but also independent service providers, you owe it to your technicians to empower them with the right tools for the job.

You owe it to your customers, too. And, having established fantastic efficiencies in field service management, there is far greater scope to drive value and ROI by optimising your service part supply chain. Enable your techs to drive an awesome customer experience at every interaction by ensuring the right part for the job is at hand when and where they need it.

[1] AberdeenGroup, “Service Parts Management 2013: Align Planning and Forecasting with Efficient Resolution”, p. 1

[2] AberdeenGroup, op. cit., p. 3

[3] AberdeenGroup, op. cit., p. 7

[4] WBR, “Where Service Meets Sales: Automating for the Future of Field Service”, p. 10

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply