Can business intelligence change the fragmented service management supply chain? (Part One)

Jan 06, 2014 • Features • Management • management • business intelligence • centrex

With the current economic business pressure, reducing costs in the service management supply chain without compromising customer satisfaction is a challenge which must be faced head on. Glyn Dodd, Managing Director of Centrex Services explains why...

Facing the challenge...

Managing this balancing act requires business intelligence, which refers to the applications, tools, infrastructure and best practices which enable raw data to be transformed into significant information, and as such can be utilised to improve outdated processes in the service management arena.

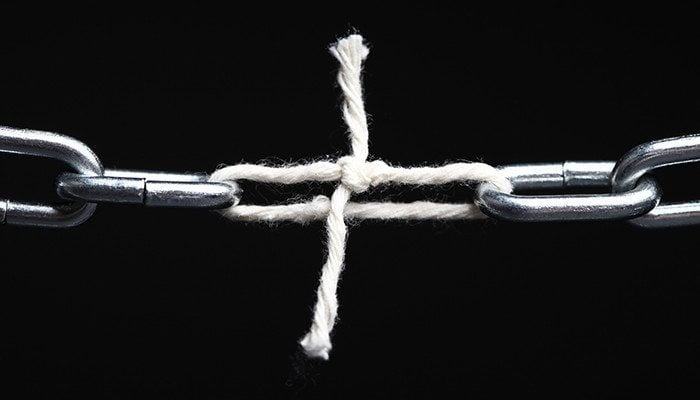

Sadly, the current service supply chain model does not use business intelligence, but relies on a silo system, in which each area of the network, namely diagnostics and scheduling, parts, logistics, field service and repair, is run by a separate company.

Although the majority of companies working within the service supply chain use this silo model, there are major pitfalls to doing so which seem to be overlooked by the decision makers which strategically drive the agenda.

Quite simply, these are issues that cannot be overlooked in modern service management.

We know the service supply chain model has been working inefficiently, with separate entities running each sector of the network. Unsurprisingly, the communication between these areas is often found lacking, as an issue which the diagnostics team are unable to resolve is simply passed on to the next stage, when in reality it may not have been necessary to do so.

The current model invariably results in the deployment of field service engineers, regardless of the scale of the problem, due to a lack of business intelligence. The cost-effectiveness of such a system must therefore be scrutinised.

There are three key elements to the service supply chain which transcend each of the five silos. By studying the people, processes and data which unite to create the service supply chain, while simultaneously identifying the inefficiencies within these silos, each element can be challenged. Ultimately, this will culminate in a far more efficient network.

Correctly skilled representatives create cost-effectiveness in service management

The three key elements which are vital to the functionality of the service supply chain must be dissected to create the most effective model available. The first of these are the people who represent businesses in the service supply chain. This is the element which is easiest to directly challenge, as this can be controlled through efficient management of correctly skilled representatives.

Personally, I believe that the current silo model within the service supply chain is in fact impeding such change.

Communication is of paramount importance in all businesses, and this applies to those working in the service management, where we live and die by the level of customer service we are able to offer.

It is therefore unacceptable that the communication silos which the majority of businesses seem to rely upon result in a system where cross-silo communication is so poor. This is especially poignant when it is the customers who pay the price. It is hard to believe, when some businesses utilise an integrated service network which improves communication, that the silo structure continues.

A recent study by the Aberdeen Group shows service supply chain customers agree with this sentiment. 58 per cent of respondents state they want to see an improvement of diagnosis of triage at the initial call level. With further statistics showing there is a 24 per cent increase in first-time fix performance, from 62-86 per cent, when all calls are routed via triage, it is clear that such intelligent communication can increase service level agreements (SLA) and in turn, customer satisfaction levels.

Inefficient processes must be challenged

Customer satisfaction levels cannot be increased solely through challenging the service supply chain businesses representatives. Alongside this, processes must also be scrutinised to construct an efficient service in which business intelligence can be utilised.

With business needs evolving continuously, the processes which are currently commonplace within the network cannot be sustained in the long term.

Although this is a vital step in the evolution of the service supply chain, this message is not reaching the relevant decision makers.

Those decision-makers who strategically alter the function within the service supply chain do not necessarily have the knowledge required to alter the inefficient processes which currently plague the system.

With businesses worried about maintaining their profit margins in these difficult times, altering the processes they use can seem like an unnecessary burden, which is then wrongly linked to excess spending. If they used a leansource approach to integrate the service supply chain rather than tactically selecting separate companies, efficiency levels would increase, while spending decreases and complex issues are transformed into competitive advantage.

A study by research organisation McKinsey looking into the priorities in the global supply chain support this. 61 per cent of respondents cited reducing operating costs as a priority over the past three years, which is a task manageable through creating more efficient processes within the service supply chain. Once achieved, the percentage of SLA’s which are successfully achieved will increase without any additional pressure being applied on the deployed field service engineers.

Read the second part of this feature here where Glyn outlines why Big Data isn’t the answer to solve all the service management industries issues, why failure is a good thing, and why true Business Intelligence is perhaps the key to unlocking a successful future for service management...

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply