Can business intelligence change the fragmented service management supply chain? (Part Two)

Jan 21, 2014 • Features • Management • management • big data • business intelligence • centrex • centrex services • glyn dodd • Service Management

In the first part of this two part feature Glyn Dodd, Managing director of Centrex Services discussed how with the current economic business pressure, reducing costs in the service management supply chain without compromising customer satisfaction is a challenge which must be faced head on...

Now in the concluding part of this feature Glyn outlines why Big Data isn’t the answer to solve all the service management industries issues, why failure is a good thing, and why true Business Intelligence is perhaps the key to unlocking a successful future for service management…

Big data is not the answer

The final element of deriving complete business intelligence is the data. The arrival of complex data analytics may seem to be the answer to such issues, but I believe that the data alone is not enough to improve the current state of the service supply chain.

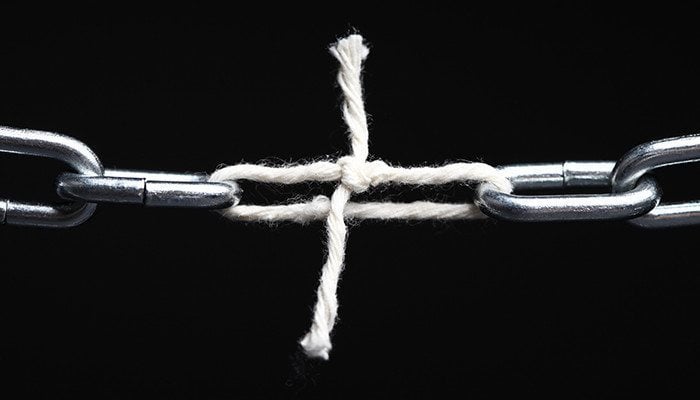

There is a widely held belief that generating ever increasing amounts of data is the answer to all our service supply chain needs, but alone it is irrelevant if not turned into useful information. It’s the business intelligence transforming this into relevant information which is vital for the creation of an efficient, integrated service supply chain, abolishing the silos that plague the current model.

Companies such as Centrex Services source business intelligence from reason code data and apply a layer of diagnostics. The codes detail the circumstances that have caused the code to be raised and the associated completion code. Rather than just documenting each code and applying the same reasoning to each circumstance, the business identifies repetitive causes and designs a solution to resolve the issue, without it reoccurring.

This intelligence was applied when we identified a recurring problem on the point of sale system at a fast food outlet. A plastic part of the POS hardware was continuing to break, causing the same reason code in the majority of the support calls. When the business analysed the fault, they found the operators were leaning on the part of this hardware during use. The plastic was simply not robust enough. By tooling a metal replacement part, the problem was resolved permanently.

Delivering customer satisfaction is a critical part of any business and deriving intelligence plays a large part in the experience. Diagnostics of reason codes is therefore vital, yet many do not see the long term benefits which have an adverse affect on customer satisfaction within the service supply chain.

If businesses diagnose the reason codes, business intelligence can be created, which in turn can be used to offer improved SLA’s, rather than accepting a failure rate.

Why should we plan to fail?

In addition to the people, processes and data, the service supply chain is heavily reliant on service level agreements. We need to question the current ethos in place throughout the service supply chain, claiming some companies are in fact preparing for failure.

There are circumstances where SLA’s are not being met as a direct result of people and processes being deployed without applying context to the data which has been sourced. I also question why SLA agreements are being signed allowing up to a 15 per cent failure rate when the deployment of business intelligence can realistically create a network in which success is inevitable.

The need for such change was identified in a business intelligence not utilising business intelligence, which resulted in an SLA being missed.

A client of ours works closely with a very well known American diner chain and have in place an agreement which states once a call has been made to report a technical fault, there must be a field-service engineer on-site to resolve the issue within four hours.

The issue here was, these calls can come in at any time of the day and the mentality was that the SLA must be met at all costs. So, when a call reporting faulty point of sales systems was placed at 1.00pm, processes were set in motion to guarantee an engineer was on-site by 5.00pm.

However, once they arrived, they were turned away, as the restaurant was unable to accommodate the work during their busiest period as this would result in a decline in productivity which in turn can lead to a loss of custom. Ultimately, the SLA was not met.

This demonstrates just how vital it is that the service supply chain changes, as had business intelligence been utilised, there is no way an engineer would have been sent to a restaurant during such a busy time.

Business intelligence is the future

Efficient communication, processes and correct analytics provides the business intelligence needed to simplify the fragmented supply chain. Simplification leads to more efficient service delivery, guaranteed SLA’s, greater customer satisfaction and ultimately transforms the service supply chain for competitive advantage.

Now is the time for senior decision makers to challenge all elements of the chain; without constant innovation and new thinking the industry will continue to be perceived as a laggard – a disparate set of fragmented, commoditised services that fail to meet the required standard.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Field Service News is published by 1927 Media Ltd, an independent publisher whose sole focus is on the field service sector. As such our entire resources are focused on helping drive the field service sector forwards and aiming to best serve our industry through honest, incisive and innovative media coverage of the global field service sector.

Leave a Reply